How to Remove Screen Printing from a Shirt?

Screen printing is a prevalent method for adding designs to shirts, but there are times when you might want to remove that printed design. Whether it's an old logo you no longer like or a misprint you want to correct, here are several effective ways to remove screen printing from your shirt. Additionally, we'll touch on some aspects related to flexo printing machines, which are important in the broader printing industry.

1. Using Acetone or Nail Polish Remover

Acetone, a key ingredient in many nail polish removers, is highly effective in dissolving screen printing ink. This method has a high success rate, around 70%. Here's how to do it:

- *First, identify the fabric of your shirt. If it's made of polyester fiber, acetone may not be necessary as screen prints on polyester can sometimes be removed more easily by other means. For cotton or denim shirts, this method is generally safe.

- *Soak a cotton ball or a cloth in nail polish remover. Dab an inconspicuous area of the screen print first to test if the chemical will damage the fabric.

- *Then, gently rub the soaked cotton ball or cloth over the print in a circular motion. You may need to repeat this process for 10 - 15 minutes until the ink starts to dissolve and the print fades away.

- *After removing the print, wash the shirt thoroughly to get rid of any remaining acetone and ink residue.

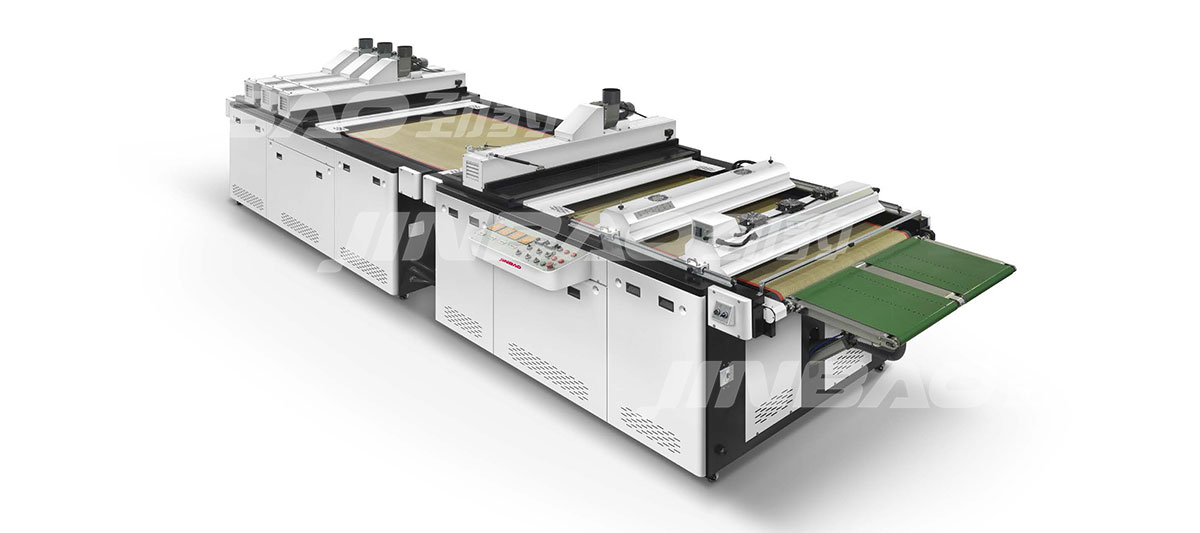

In the context of the printing industry, flexo printing machines are often used in large - scale production. These machines, which use flexible relief plates to transfer ink, are known for their versatility. They can print on a variety of materials, including those similar to the fabric of shirts we are dealing with here. The inks used in flexo printing, like the screen printing inks we are trying to remove, need to be carefully formulated to ensure good adhesion and colorfastness.

2. The Heat Gun or Iron Method

A heat gun can be an effective way to remove screen prints on t - shirts and other clothing items, with an approximate success rate of 80%. However, not everyone has a heat gun at home. An iron can be used as a substitute.

- *Place the shirt on an ironing board. Put a towel inside the shirt, directly underneath the screen print, to protect the inner fabric.

- *Soak a white cloth in cold water and squeeze out the excess. Place this damp cloth over the screen print design. The damp cloth serves as a heat barrier to prevent the fabric from getting burned.

- *Set the iron to a medium - high heat setting (without steam). Press the iron firmly over the damp cloth. Keep the iron in place for a few seconds, then move it around the print area.

- *As the damp surface dries up, remove the iron. Be careful not to let the fabric burn.

- *Use a sharp knife (be extremely cautious not to damage the fabric) to gently scrape the edges of the design. This makes it easier to start peeling the print.

- *Slowly peel the print off the shirt by hand.

Full Automatic Screen Printing Machines also rely on heat in some processes, such as drying the ink after it has been transferred to the substrate. The heat source in a flexo printing machine needs to be carefully controlled to ensure that the ink dries evenly and that the printed material is not damaged.

3. Using a Plastisol Remover

Plastisol is a common type of ink used in screen printing. Special plastisol removers are available in the market that can effectively remove this type of ink.

- *Soak a soft cloth in the plastisol remover.

- *Place the soaked cloth over the screen print design and leave it for at least 20 - 30 minutes. This allows the remover to penetrate and break down the ink.

- *Use a light - bristled brush to gently scrub away the flaking bits of the design.

- *Wipe off the remaining plastisol remover with another soft cloth.

- *You may need to scrape off any remaining ink within the fabric fibers by hand.

- *Wash the shirt before wearing it again to ensure there is no lingering odor.

Flexo printing machines may also use inks similar to plastisol in some applications. The choice of ink in both screen printing and flexo printing depends on factors such as the type of material being printed on, the desired finish, and the durability requirements of the print.

4. Abrasive Methods: Sugar Scrub or Baking Soda Paste

These are relatively safe methods that don't involve heat or harsh chemicals.

- *Sugar Scrub: Pour a teaspoon or more of sugar over the screen print design. Use a damp cloth to rub the sugar over the print in circular motions. This method works better on fresh prints, but it can also be tried on older ones.

- *Baking Soda Paste: Make a paste by mixing baking soda with a little water. Apply the paste over the area with the print. Use a brush to scrub the area gently. The abrasive nature of the baking soda helps to remove the ink.

Flexo printing machines, in contrast, use more precise methods of ink transfer, such as through the use of anilox rollers. These rollers are engraved with tiny cells that hold and transfer a specific amount of ink to the flexo plate, ensuring accurate and consistent prints.

5. Using a Spot Removal Gun

If you have a spot removal gun (designed for removing stains and in some cases, small areas of unwanted prints), you can use it to remove screen printing. However, this method is more suitable for small errors or prints.

- *Check the manual of the spot removal gun for the recommended spot removal fluid.

- *Fill the gun with the appropriate fluid.

- *Spray the fluid directly onto the screen print design.

- *Wipe the area with water and a soft cloth to remove the dissolved ink.

Automatic Screen Printing Machines, with their complex systems for ink transfer and registration, are designed to produce high - quality prints on a large scale. They can handle various printing jobs, from simple labels to complex packaging designs, much like how different methods are required to handle different types of screen prints on shirts.

When attempting to remove screen printing from a shirt, always test the method on a small, hidden area of the fabric first to ensure that it doesn't cause any damage. With these methods, you can transform your old shirts with unwanted screen prints into something fresh and new.