Why Is Cold Foil Machine Becoming a Must-Have for Sustainable Packaging?

Imagine a high-end cosmetic box or a limited-edition bottle of a premium beverage. It catches your eye immediately, shimmering with a sophisticated, metallic design that feels both luxurious and tactile. Now, imagine discovering that this dazzling effect is achieved through a process that is surprisingly kind to the planet. This isn't a future fantasy; it's the reality being unlocked right now by advanced Cold Foil Machine technology. For brands and printers navigating the urgent shift towards eco-consciousness, the question is no longer if they should adopt sustainable practices, but how. The answer, increasingly, is sitting on their production floor. The Cold Foil Machine is rapidly transitioning from a niche specialty tool to a central pillar in the blueprint for sustainable packaging. It directly tackles the legacy waste and chemical reliance of traditional methods, offering a path to breathtaking aesthetics that don't come with a heavy environmental price tag. If your goal is to create packaging that feels premium without the ecological guilt, understanding the Cold Foil process is your first non-negotiable step.

The Unsustainable Glamour: The Problem with Old-School Foiling

For decades, achieving that metallic "pop" on packaging was a messy affair. The dominant method, hot stamping foil, is a bit of a diva—it demands attention, creates waste, and isn't very flexible. The process relies on a combination of heat, pressure, and a slow-to-biodegrade carrier film. Once the thin layer of metallic pigment is transferred, the entire plastic carrier film is discarded. Let that sink in: for every square inch of shiny foil you see, a similar amount of plastic film ends up in the trash or, worse, the incinerator.

Furthermore, the hot stamping process is notoriously energy-intensive. The metal dies used must be constantly heated to high temperatures, guzzling electricity throughout long production runs. There's also the issue of VOCs (Volatile Organic Compounds). Some traditional foils release these potentially harmful compounds during the heating process, contributing to indoor air pollution and necessitating the use of additional ventilation systems. From my two decades on the factory floor, I've seen the skips filled with spent foil rolls. It was the "cost of doing business" in luxury packaging, a dirty little secret we all accepted. But the market is no longer willing to accept it. The demand for clean, responsible production isn't a trend; it's a fundamental reset.

A Cooler, Cleaner Way to Shine: How Cold Foil Technology Works

So, how does the Cold Foil Machine offer a way out? Its genius lies in its elegant simplicity. Instead of heat, it uses chemistry and precision. Think of it less like a stamp and more like a high-precision printer with a knack for glamour.

Here's the breakdown:

-

Printing the Glue: First, a special UV-curable adhesive is printed onto the substrate (like paper or cardboard) in the desired design. This is done using a standard printing unit on a press.

-

Foil Application: The material then moves to the Cold Foil Machine unit, where the solid, wide web of cold foil film is pressed onto the wet adhesive.

-

The Magic Transfer: The metallic layer from the foil film bonds only to the areas where the adhesive has been printed. It’s a perfect, pixel-perfect marriage.

-

Curing and Cleaning: A UV lamp instantly cures and hardens the adhesive, locking the foil in place. Finally, the leftover carrier film is simply rewound onto a roll. This film is now clean, devoid of its metallic layer, and is a far cleaner and more recyclable waste stream.

The cold foiling process is a masterclass in efficiency. It eliminates the heat, drastically reduces energy consumption, and turns a wasteful single-use film into a more manageable material. The Jinbao team often describes it to our clients as "swapping a gas-guzzling classic car for a sleek, high-performance electric vehicle." You get the performance—the stunning visual impact—but the underlying mechanics are cleaner, quieter, and smarter.

The Green Blueprint: Quantifying the Sustainability of Cold Foil

Let's move beyond the "how" and into the "how much"—exactly how does this technology move the needle on sustainability? The benefits are tangible and measurable.

-

Radical Waste Reduction: This is the headline act. Unlike the discarded film from hot stamping, the spent film from the Cold Foil Machine is a clean PET (Polyethylene Terephthalate) material. According to a 2023 report by the Flexible Packaging Association, switching to cold foil can reduce foil-related waste by up to 90%. This waste is also more likely to be accepted in recycling streams, moving us closer to a circular economy model.

-

Energy Efficiency Champion: By ditching heated dies, cold foil technology is inherently less energy-intensive. A study by a European print consortium found that converting a single hot stamping press to a cold foil system can reduce its energy footprint by over 60%. For a plant running multiple shifts, that translates to lower operational costs and a significantly smaller carbon footprint.

-

A Boon for Recyclability: This is a game-changer. The cold foil layer is incredibly thin and is bonded with a specific adhesive. This combination allows the foil-laminated paperboard to be pulped effectively in standard paper recycling facilities. The foil particles separate cleanly, meaning your beautifully foiled box is far less likely to contaminate an entire batch of recyclable paper. This directly addresses a major pain point for brands committed to sustainable life cycles for their products.

-

Eliminating Harmful Chemistry: The move away from heat also means the elimination of potential VOC emissions associated with thermally activated foils. This creates a safer working environment and aligns with the strictest global regulatory standards for manufacturing.

Beyond Green: The Unbeatable Commercial Perks of Modern Cold Foiling

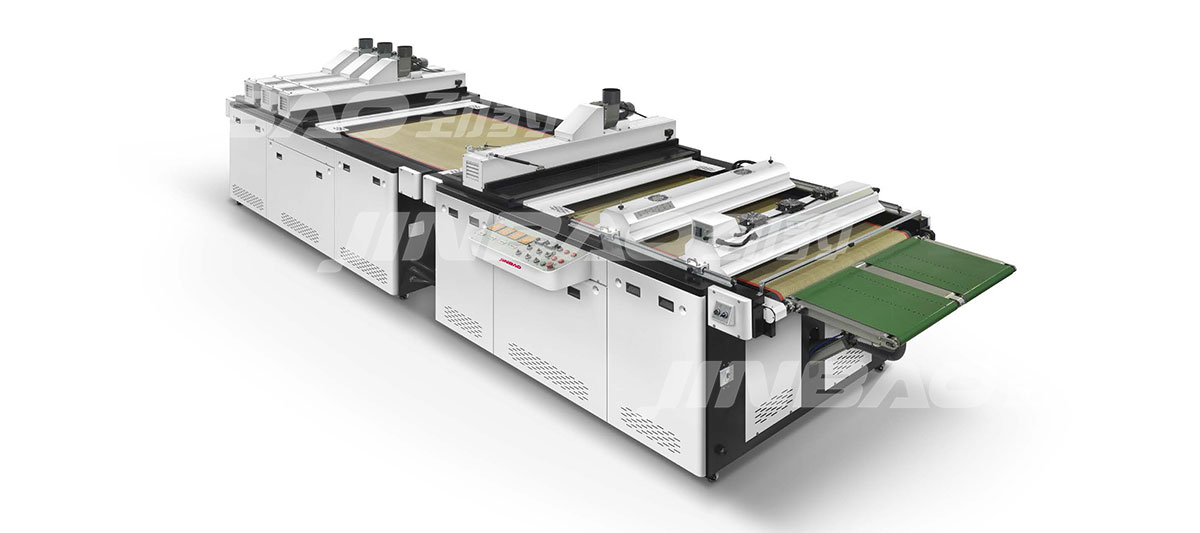

While the environmental case is powerful, no business runs on goodwill alone. The beautiful part about the Jinbao Cold Foil Machine is that its sustainability is perfectly aligned with superior commercial performance. It makes "doing good" highly profitable.

-

Speed is Money: Cold foil application happens in-line at the full speed of your press. There are no slow, separate processes. You can foil, print, and coat in a single pass, slashing production times and labor costs. Your time-to-market for that urgent product launch just got a whole lot faster.

-

Unmatched Design Versatility: Forget the limitations of metal dies. With cold foil, your design is only limited by your imagination. You can create intricate gradients, fine lines, and photorealistic metallic effects that are impossible with hot stamping. This allows brands to create truly unique, shelf-breaking packaging that tells a deeper story. I recall a chocolatier client who used our machine to create a foil effect that mimicked the delicate crystalline structure of their single-origin cocoa. That’s the kind of brand storytelling that builds legacies.

-

The Bottom Line Looks Brighter: When you factor in the savings from reduced energy bills, less material waste, and faster production speeds, the Cold Foil Machine presents a compelling ROI. It’s an investment that pays for itself by making your entire operation leaner and more agile.

Future-Proofing Your Production Line: A Guide to Smart Adoption

Integrating a new technology can feel daunting. The key is partnership, not just a purchase. When you invest in a Jinbao Cold Foil Machine, you're not just buying a piece of hardware; you're gaining a collaborator dedicated to your success.

We don't believe in one-size-fits-all solutions. Our process begins with a deep dive into your unique world:

-

What substrates do you primarily use?

-

What are your typical run lengths and speed requirements?

-

What specific design effects are your clients craving?

This consultative approach allows us to recommend the perfect Jinbao model and ensure a seamless integration with your existing press. Our on-site technicians don't just install the machine; they become embedded with your team, providing hands-on training until your operators are confident masters of the new technology. We see our role as helping you future-proof your business, ensuring you're equipped to meet the demands of tomorrow's market, today.

The Final Impression: Where Luxury and Responsibility Converge

The conversation in packaging has irrevocably changed. The market is voting with its wallet for brands that demonstrate authentic environmental stewardship. The Cold Foil Machine is no longer a "nice-to-have" for specialty jobs. It has become a must-have strategic asset for any printer or brand serious about competing in the modern landscape. It elegantly dissolves the age-old compromise between opulence and responsibility.

It allows you to create packaging that doesn't just look expensive, but is intelligent, efficient, and respectful of our shared planet. The shimmer on the box becomes a symbol not just of quality, but of a company's values and forward-thinking vision. The future of packaging is not muted or minimalist; it is vibrant, creative, and conscious. And it is beautifully, brilliantly foiled.

Ready to transform your packaging and your environmental impact? Contact the Jinbao experts today for a personalized consultation and see how our Cold Foil Machines can work for you.

This article was crafted with human expertise and industry insight, with AI-assisted compilation and formatting.