Which Semi Auto Screen Printer Fits Glassware Needs

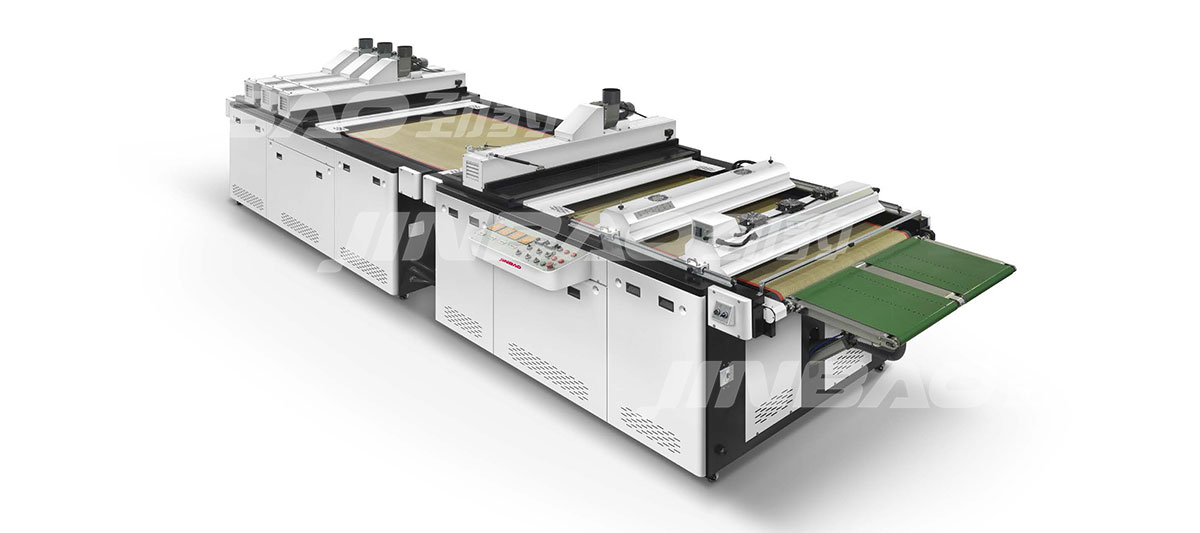

A well-designed, semi-automatic screen printing machine optimized for glass products, equipped with a precise registration system, adjustable stroke control, and a robust curing system, is crucial. For many businesses, from craft breweries to cosmetics brands, the JinBao series, particularly models like the JB-750II, has become the preferred choice because it is specifically optimized for cylindrical and irregularly shaped glass surfaces.

1. Precise Registration and Fine Adjustment: This is essential. For multi-color printing on glass bottles—such as complex craft beer labels—the screen must land in the exact same position every cycle. Choose a machine with fine-tuning knobs on the print head and platen. The JinBao equipment I've used all feature these fine-tuning adjustments, saving hours of setup time and avoiding many headaches.

2. Adjustable Printing Stroke and Pressure: Delicate perfume bottles and sturdy beer mugs require different squeegee pressures. High-quality semi-automatic printers allow control over stroke length, angle, and downforce. This ensures complete ink transfer without damaging the screen or distorting the image.

3. Integrated Powerful Curing System: Printing is only half the battle. The ink must be permanently cured. For glass products, this typically means using UV-curable inks and having a built-in or inline UV curing oven. The synergy between the printer's dwell time and the dryer's conveyor speed is critical. Disjointed settings will lead to defects.

4. Versatile Clamping Fixtures (Mandrels and Conical Clamps): The best glass screen printing equipment comes with or supports a variety of clamping fixtures. Can it securely hold narrow-necked wine bottles and wide-mouthed Mason jars? JinBao's strength lies in its customizable platen system, allowing processors to create or order fixtures for virtually any container.

Fully automated systems are ideal for mass production of 10,000 identical bottles. Manual printing is suitable for 50 prototype mugs. But for the large middle market—production runs of 500 to 5,000 pieces, often requiring frequent product changes—a semi-automatic screen printing machine is the best option. It can increase an operator's output by 3-5 times compared to manual printing, while maintaining a level of flexibility unmatched by robots.

Choosing the right semi-automatic screen printing machine for your glassware is more than just a purchasing task; it's a strategic decision that determines your product quality and production capabilities. By focusing on precision, versatility, and a robust support ecosystem—such as brands like JinBao that offer customized solutions—you can transform a challenging process into a smooth and profitable operation. Stop struggling with unsuitable printing machines for your round bottles. Invest in a tool designed for the job.

Ready to discover the machine that truly fits your glassware needs? Contact our team of experts today to discuss your specific bottles, jars, and cups. We'll provide you with a tailored JinBao solution and demonstrate its superior performance with an on-site demonstration.

SEO Keywords

semi automatic screen printing machine

glassware screen printer

semi auto screen printer

JinBao screen printing machine

printing on glass bottles