Silkscreen machine, see what makes it different!!!

We use a lot of silkscreen machine in our daily life, so everyone knows less about screen printing machines. Next, screen printing machine manufacturers will introduce to you one by one the scope of application and product advantages to usage methods!

Application range of silkscreen machine

1. Packaging and printing

The main service object of the screen printing machine in the packaging industry is the screen printing industry, such as printing high-end packaging boxes, packaging bottles, cigarette packs, etc.; in addition, with the continuous development of today's computer technology, various software continue to appear, especially The production of CDs for cultural entertainment, TV movies, and various publications are increasing day by day. 92% of the printing of company logos, images, and text on this CD disc is by screen printing.

2. Advertising printing

There will be more markets for screen printing in commercial advertisements, especially electrical appliances companies, tobacco and alcohol companies all attach great importance to the role of advertisements in order to promote their own images. The timing and quality of advertising determine the company's share of the market. Therefore, various electrical advertisements, outdoor advertisements, and commercial advertisements provide a broad space for screen printing.

3. Circuit printing

In the field of the electronics industry, screen printing has a share of 80%. For example, in the production of a TV, screen printing is used in many places, and the development of large-scale flat-panel display devices such as display screens (PALC) is increasingly inseparable from screen printing.

4. Handicraft printing

With the development of my country's western region and the process of rural urbanization, the increase in ceramic tile production lines is strong. In addition, my country is a large country of ceramics. In addition to meeting a large number of domestic needs, it also exports to more than 150 countries and regions. The screen printing of ceramic decals plays a pivotal role in China's screen printing industry.

Silkscreen machine advantages

The products printed by the screen printing technology of the screen printing machine are bright in color and can be stored for a long time, and are also suitable for mass industrial production. They are not limited by the shape and size of the printed items, as long as they are flat or curved spherical surfaces, etc. Shaped objects can be printed with a screen printing machine.

Advantage 1: Good ink adhesion

Silk screen printing uses silk screen printing ink. The printed product pattern not only has good adhesion and a thick ink layer, but also does not fade or fade, and maintains bright color for a long time.

Advantage two: high printing quality

The screen printing machine has a multi-color printing sensor device, and the screen printing operator only needs to make a slight adjustment to accurately align the printing color and dot, which improves the quality of the post-printing product.

Advantage 3: Large-area printing is possible

The screen printing machine can evenly print the substrate with a large area of background color and dots. When printing a large-area substrate with other printing machines, it is easy to form a phenomenon of blurred dots, while the coating of the substrate printed with a screen printing machine is clear and Can keep long-term color does not fade.

Advantage 4: Can be used in conjunction with a variety of machines to improve efficiency

The screen printing machine can be used in conjunction with a variety of machines, such as UV dryers, coating die-cutting machines, slitting machines, cutter machines, and rewinding machines, etc., which can greatly improve printing efficiency and save certain costs.

Advantage 5: Fast printing speed, up to 5000 prints/minute

Silkscreen machine With the advancement of technology, the screen printing machine has changed from manual to automatic, and the printing speed has also changed continuously. From the original 70 prints/minute to 5000 prints/minute, the rapid increase in printing speed has continuously improved production efficiency.

According to the way of use

(1) Manual screen printing machine: generally composed of hinge support, printing platform, and screen plate, all actions are manually operated.

(2) Semi-automatic screen printing machine: various actions during printing are partially automatic, and the rest are still manual screen printing machines. It is generally called a 1/4 automatic screen printing machine for ink scraping, ink distribution, and screen frame, and a 1/2 automatic screen printing machine for ink scraping, ink distribution, screen frame, and substrate adsorption. machine. In addition, the substrate feeding can also be automatic as a 3/4 automatic screen printing machine.

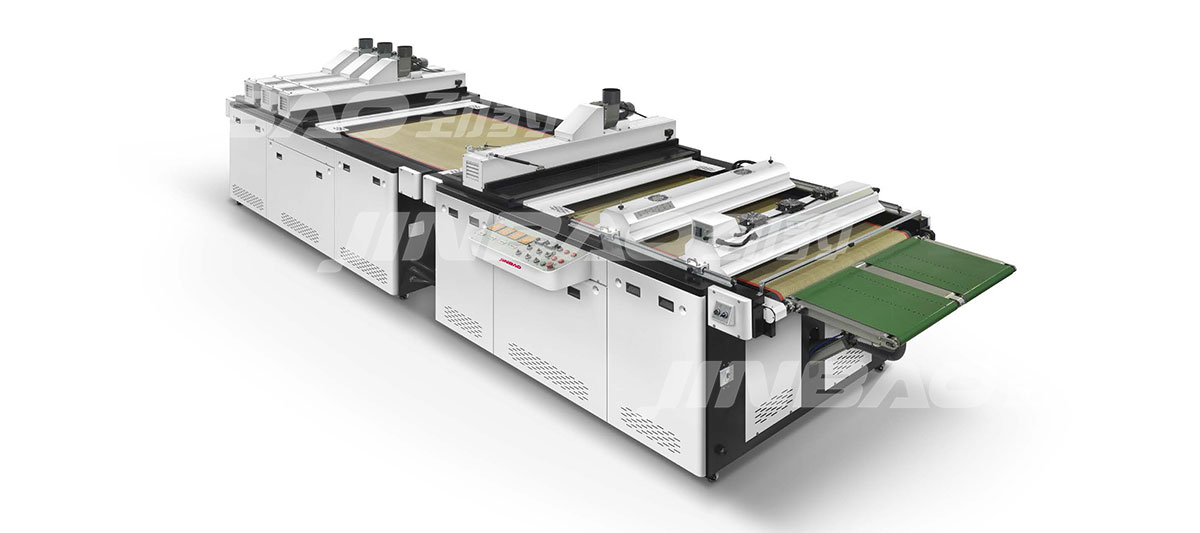

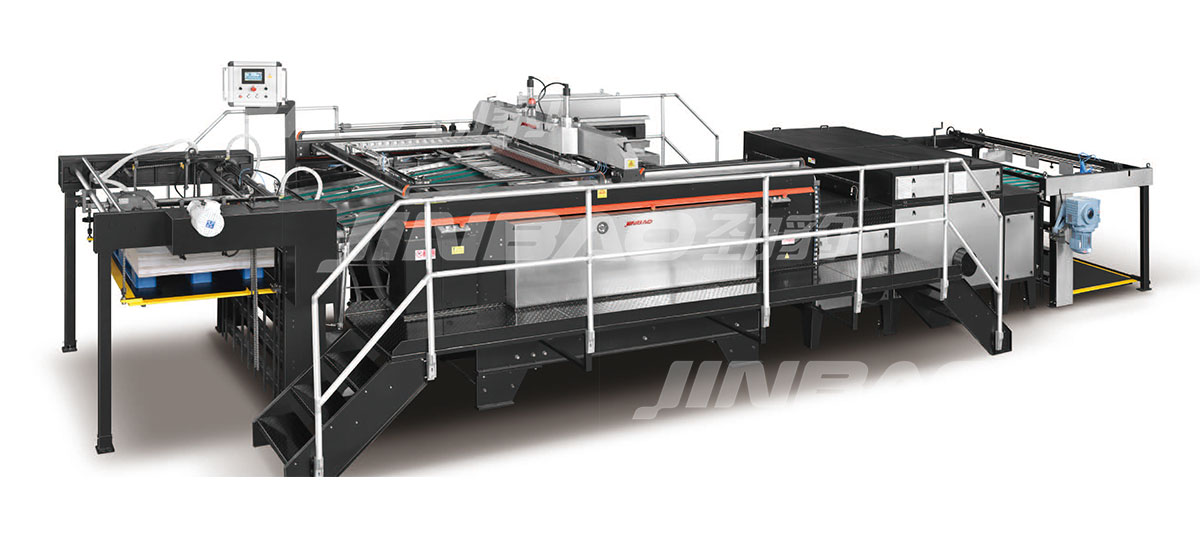

(3) Automatic screen printing machine: add automatic printing lifting, conveying, drying, and receiving stacking mechanisms before and after the 3/4 automatic screen printing machine, the printing speed is significantly higher than that of the semi-automatic machine, up to 1500 prints /hour or more.

(4) Screen printing linkage machine: It is composed of several sets of printing, drying devices, bronzing, creasing, film coating, die-cutting, and other devices connected in series. The substrate is continuously fed in roll type, with automatic unwinding, automatic winding, and positioning control mechanisms, which can ensure stable speed, accurate overprinting, and consistent tension. The whole machine can be controlled by a computer. It is a screen printing machine with high efficiency and full functions for multi-color printing.