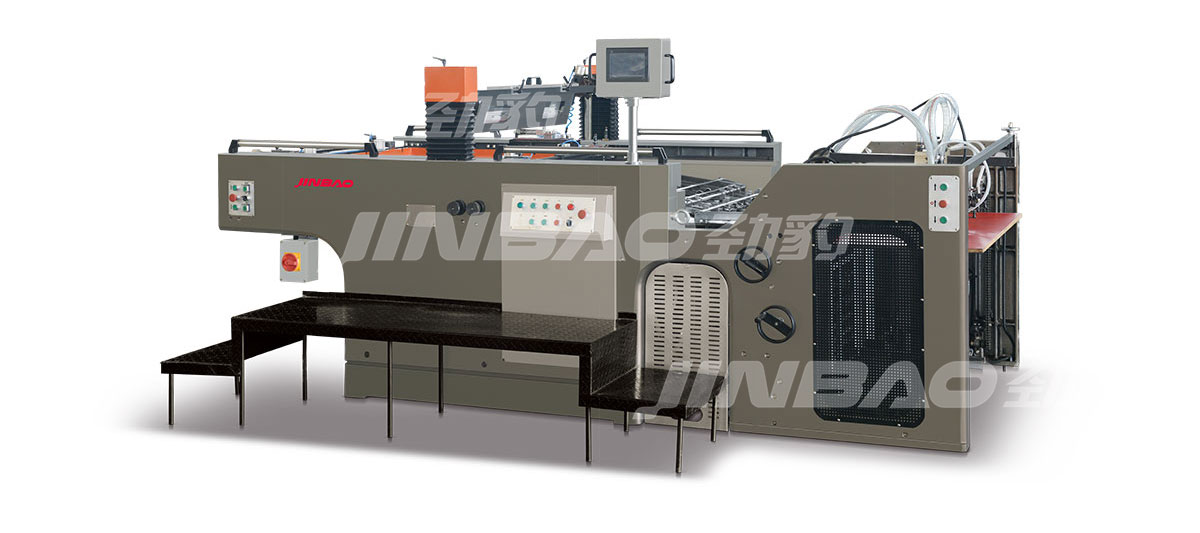

JB-A Series Full Automatic Stop Cylinder Screen Press which adopts the classical stop cylinder technology with the advantages such as: paper located exactly and steadily, high precision, high speed, low noise, high degree automatization and so on, it is suitable for printing on ceramic and glass applique, electron industry (film switch, flexible circuitry, meter panel, mobile telephone), advertisement, packing and printing, brand, textile transfer, special technics etc.

| Model | JB-720A | JB-800A | JB-1020A |

| Max. printing size | 720×500mm | 800×590mm | 1020×710 mm |

| Frame size | 880×880 mm | 1070×1070 mm | 1140×1280 mm |

| Paper thickness | 108~400 g/m2 | 108~400 g/m2 | 108~400 g/m2 |

| Border | ≤10mm | ≤10mm | ≤10mm |

| Printing speed | 1000-3600 pcs/h | 1000-3300 pcs/h | 1000-3000 pcs/h |

| Power | 3Φ 380V 50Hz 10.5Kw | 3Φ 380V 50Hz 10.5Kw | 3Φ 380V 50Hz 14.64 kw |

| Total weight | 3500kg | 4000kg | 5500 kg |

| Overall size | 3.3x2.45x1.69m | 3.48x2.58x1.69m | 4.15×2.84×1.7m |

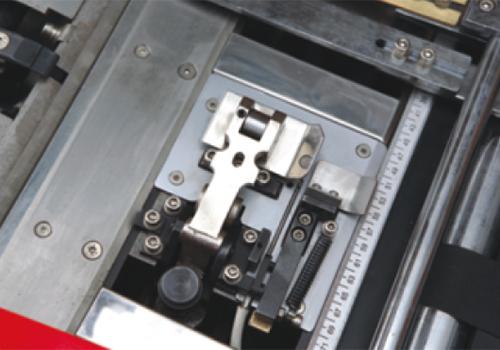

Stop cylinder mechanism

The automatic stop cylinder guarantees that the front end of the printing substrates can be conveyed to the gripper with extreme high accuracy. Meanwhile, the gripper and side lays are both equipped with detecting sensor to monitor the location of the printing substrates, which effectively minimizes the reject rate of printing.

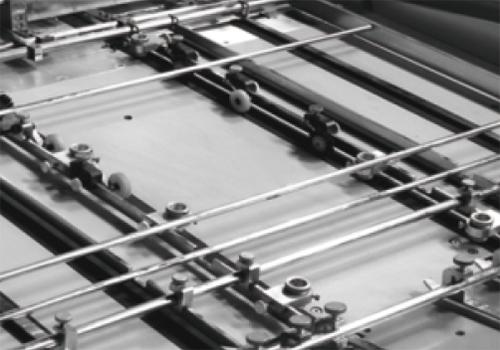

Transfer system

The vacuum absorption device under the feed board coordinates with the paper stacking and pressing structure guaranteeing smooth delivery of a variety of printing substrates.

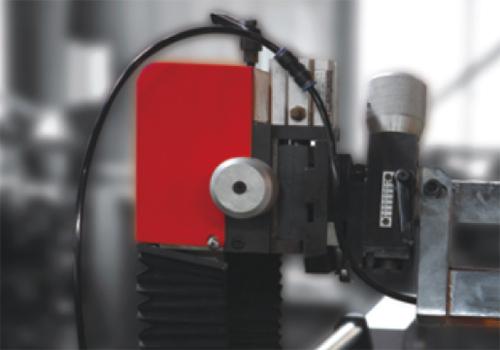

Squeegee system

Two cams control the actions of the squeegee and flood bar respectively. The squeegee is equipped with a pneumatic pressure kept device, allowing for clearer printing image and more uniform ink layer.

Centralized lubrication system

Automatic lubrication for main transmission and main parts effectively enhance the use precision and prolongs the machine's life.

The screen frame can be pulled out not only facilitating the registration of substrates and the adjustment of feeding, but also making the cleaning of the cylinder and screen frame safer and faster. It is assembled with an ink dropping pan to prevent ink from spilling and being wasted.

PLC centralized control of the operation of the whole machine, standard configuration of touch screen and button dual operating system, provide simple operation and high degree of automation.

If you have any enquiry about quotation or cooperation, please feel free to email us jbprint@cn-jinbao.com or use thefollowing enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products

Imagine a high-end cosmetic box or a limited-edition beverage bottle. It catches your eye immediately, shimmering with a sophisticated, metallic design that feels bo...

Release Time:2026-01-27A well-designed, semi-automatic screen printing machine optimized for glass products, equipped with a precise registration system, adjustable stroke control, and a r...

Release Time:2025-12-16[Insert Featured Image: Close-up of high-end print samples showing cold foil UV finishing effects, with clear texture and luster contrast][Embed Video: Brief demonst...

Release Time:2025-12-05

GET A QUOTE