lt's used for high precision screen printing of flexible sheet material, such as PET, PVC, PC, transfer paper, label paper, lMD, MEMBRANE, electronic switch, meter panel sticker etc.

For screen printing on sheet material, the machine with several innovative design, such as front pick feeder, anti-static,ultrasonic inspecting, perfectly solve the problems offeeding adhesion and scratch; anti-static feeding units, vacuum conveyor to solve the transmission scratches, and easy to adjust; stop cylinder, front-lay and side-lay sensors to ensure the position accuracy; pneumatic blade system make the main structure simple, easy to operate and low cost of maintain; various improvements to ensure that the machine can be the perfect screen printing on substrates with 0.05-0.08mm thickness, printing precision can reach 0.03mm and can get high precision after 10times overprint.

| Specifications Model | JB-78C |

| Maximum material size (mm) | 520×780 |

| Minimum material specification (mm) | 270×350 |

| Frame size (mm) | 940×940 |

| Printing speed (Pcs/h) | 500~4000 |

| Power Specifications | 3P 380V 50Hz 17 Kw |

| Gas specifications | 225I/min 5-7Kgs/cm2 |

| Weight (Kg) | 3300 |

| Dimensions (mm) | 3230×2640×1700 |

JB-78C Automatic Stop Rotary Screen Printing Machines (Servo Version) under the premise of ensuring the quality of printed products, the full-size printing speed can reach 4200 sheets/hour. If you choose to print personalized products, the speed can reach 4500 pieces/hour. It is the best choice for shops in industries such as paper-plastic packaging, ceramic glass stickers, textiles, plastic film switches, and electronic and electrical related components.

This machine abandons the traditional single power source consisting of transmission shaft, gearbox, chain and crank, and instead drives the four moving bodies, conveyor, roller and net frame of the feeder. Three servo motors are used to drive the paper feeding drive, roller and frame respectively. Through automatic control, the synchronization of multiple functional units is guaranteed, which not only saves a large number of mechanical transmission parts, but also greatly improves the rigidity of the printing machine, reduces the error caused by the mechanical transmission device, and improves the printing quality. Quality and mechanical efficiency, increasing the automation level of the production process and improving the working environment conditions.

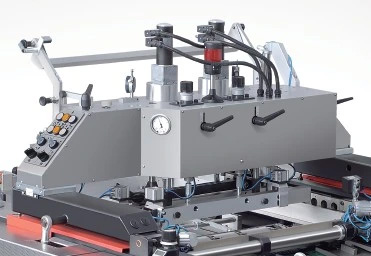

Pneumatic heavy-duty scraper system

Heavy-duty precision scraper system, making full use of advanced technologies such as electronics, pneumatics, hydraulics, machinery, and optical fibers, can preset scraper pressure, scraper pressure, and scraper drop position;

after confirmation, it will remain constant to ensure accurate control of the thickness of the printing ink layer And make sure the print quality is perfect.

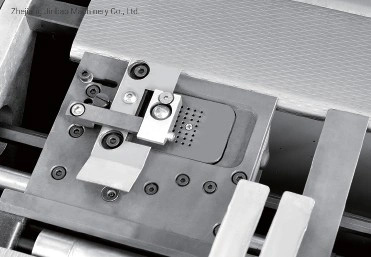

pneumatic side sleeper

The side pull and side press flat laying type will not cause damage to the printing on the graphic surface, and the printing surface and graphics will be dirty;

one-piece variable side push-pull;

push-pull precise positioning, long positioning stroke, quick and convenient positioning adjustment;

photoelectric detection system monitors printing in real time The substrate is in place, reducing the printing waste rate. The biggest advantage of this kind of pneumatic side laying is that the contact surface between the micro-suction plate and the substrate is larger.

It is different from the ball-type side laying that concentrates the force on one point, thereby preventing the printed graphics from being damaged or dirty on the double-sided printing substrate. Always reach the roller side, and notify the operator by detecting that the substrate is not in place, making the operation more convenient. Intelligent servo control automatic stop roller screen printing machine.

Separate screen frame structure

The screen frame can be separated from the transmission part and pulled out, which is convenient for the adjustment of recording and feeding;

at the same time, cleaning the drum and screen must be faster and safer;

the photoelectric sensor automatic detection system ensures the reliability of the rack action and avoids damage or damage to the main drive.

If you have any enquiry about quotation or cooperation, please feel free to email us jbprint@cn-jinbao.com or use thefollowing enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products

Imagine a high-end cosmetic box or a limited-edition beverage bottle. It catches your eye immediately, shimmering with a sophisticated, metallic design that feels bo...

Release Time:2026-01-27A well-designed, semi-automatic screen printing machine optimized for glass products, equipped with a precise registration system, adjustable stroke control, and a r...

Release Time:2025-12-16[Insert Featured Image: Close-up of high-end print samples showing cold foil UV finishing effects, with clear texture and luster contrast][Embed Video: Brief demonst...

Release Time:2025-12-05

GET A QUOTE