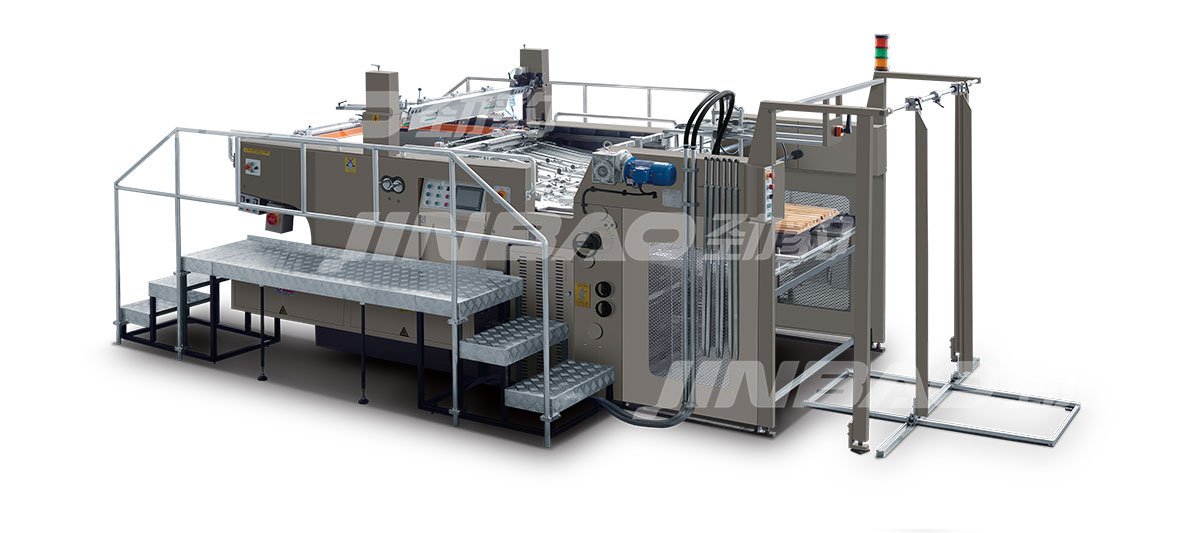

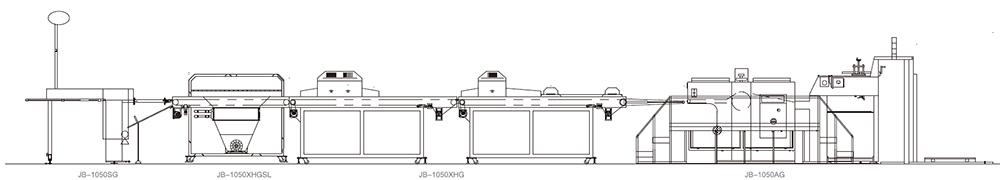

JB-1050AG full automatic stop cylinder screen press is a new model which brings in advanced design and production technology, adsorb the mature offset printing technology, innovation and has a patented technology, mainly for printing on paper and packing field. The machine adopts the classic stop cylinder, the maximum operating speed is up to 4000pcs/h; Meanwhile, the machine use non-stop feeder and nonstop collection technology, change the old operation mode which must stop machine to load substrate and collection, which eliminate the waste of time in loading and collecting, improve the printing efficiency more than 30%. It's suitable for the screen printing on ceramic and glass transfer film, advertising, packing printing, brand, textile transfer, electronics and other industries.

| Model | JB-1050AG |

| Max. printing area | 1050×750mm |

| Size of screen frame | 1300×1170 mm |

| Max. pile height | 900 mm |

| Paper weight | 90~420 g/m2 |

| Printing speed | 800-4000 pcs/h |

| Power | 3Φ 380V 50Hz 12.97Kw |

| Total weight | 6500kg |

| Overall dimension | 6.4×3.06×2.06m |

Non-stop feeder

The fully automatic non-stop feeder and pre-stacking trolley coordinating with non-stop main and sub feed programs can save work time and improve production efficiency by more than 30%. In addition, the height of the feeder has been increased to ensure the height of each loading.

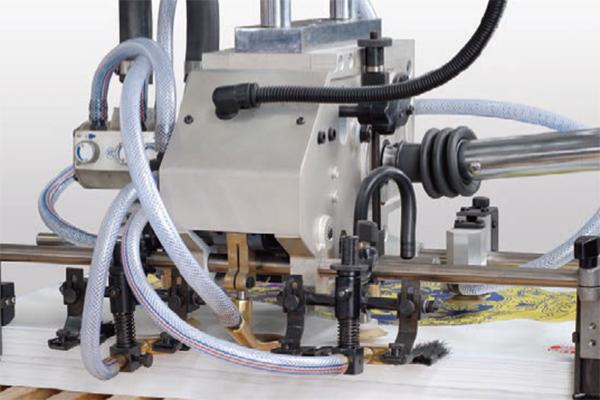

Offset print feeder head

The efficient feed head is equipped with 2 paper feed and 2 paper delivery suction nozzles, which is stable in performance and can separates sheets clearly, suitable for papers with different thicknesses. (It can be equipped with plasma blower to be adapted to papers with high static electricity content.)

Delivery board with rice grain stainless steel plate

The surfaces of whole conveying board including feed board and delivery board are fitted with rice grain stainless steel plates, which can reduce 30%~70% friction force and surface abrasion to prolong the service life of the machine.

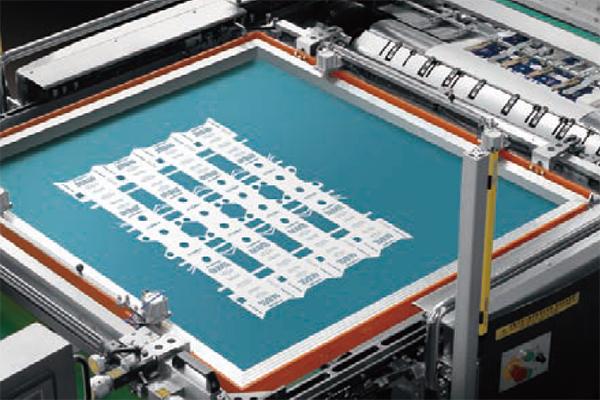

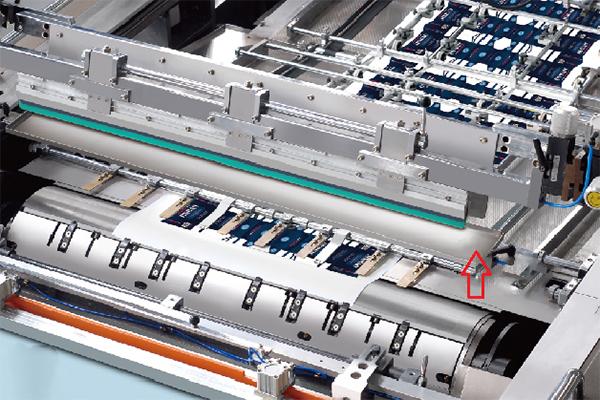

Screen frame taken out device

The screen frame can be pulled out not only facilitating the register of substrates and the adjustment of feeding, but also making the cleaning of the cylinder and screen frame safer and faster. It is also equipped with ink dropping pan to prevent ink dropping and waste.

Printing cylinder

The weight of the printing cylinder is reduced by 28% while the strength and precision are higher, which significantly reduce the vibration during mechanics operation and improve the running stability, effectively extending the machine life.

Pneumatic squeegee system with pressure kept device

The lifting and lowering of the squeegee and flood bar are controlled by cams and the pneumatic pressure kept device is equipped to guarantee uniform printing pressure so that both spot and coat can be accurately printed out.

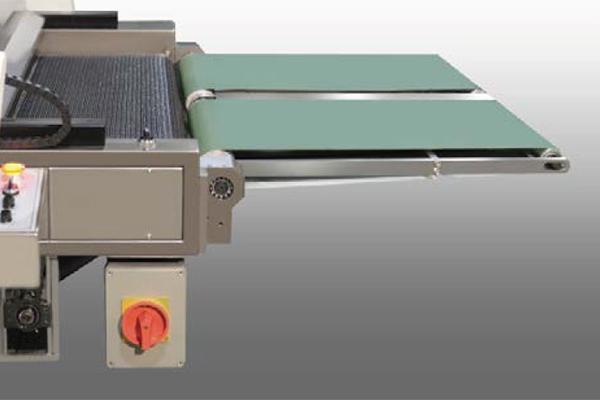

Pneumatic lift delivery board

In place of crossover delivery stand, it saves equipment occupying space. Double-wide-belt conveyor avoids the belt from tearing paper edges. With pneumatic control, it can be fold down to facilitate use.

Mesh belt transition device

The soft brush roller, arranged between multi sets of parallel mesh belts, runs in synchronization with mesh belts, which can effectively prevent substrates from being dropped so as to reduce waste.

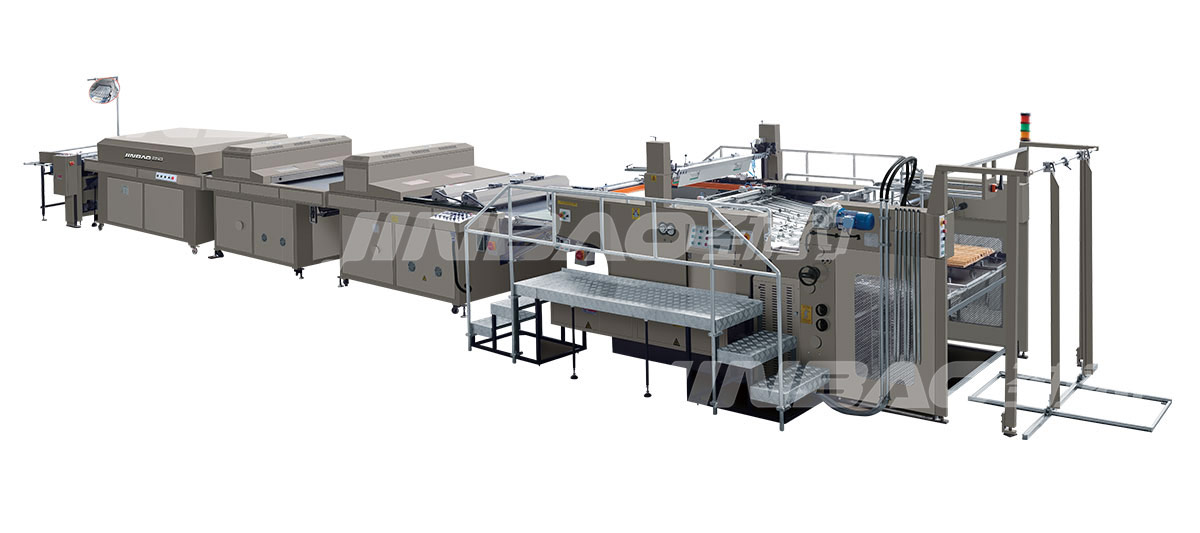

1050AG screen printing equipment can be matched with UV curing machine, paper stacker and other auxiliary equipment to constitute an efficient screen printing line.

| Model | JB-1050XHG |

| Top speed | 60m/min |

| UV power | 7.2KW×1pcs×3choice |

| 8.8kW×2pcs×3choice | |

| Wrinkle lamp power | 80W×3pcs×2choice |

| Effective solidity width | 1100mm |

| Power of conveying motor | 400W×2 |

| Adsorb motor | 1.1KW×2 |

| Power of UV blower | 0.55KW×3 |

| Weight | About 2300kg |

| Overall size | 6080×1700×1700mm3 |

| Model | JB-1050XHGSL |

| Max. speed | 60m/min |

| Power of conveyor motor | 200 W |

| Lowest temperature of cooling cavity | 15°C |

| Power of water cooler | 2.2KW(3HP) |

| Power of fan | 1.1kw |

| Weight | 730Kg+170Kg |

| Overall size | 2100×2400×1580mm3 |

The paper feeding part of the paper stacker has been redesigned, with paper receiving plate mounted below to realize non-stop delivery. Coordinated with master printing machine, it can realize non-stop operations of the whole machine, which saves work time. In addition, the paper stacker is possessed with online function that can remotely control the master printing machine, more convenient for operators to operate.

| Model | JB-1050SG |

| Max paper size | 1100×750mm2 |

| Min paper size | 350×250mm2 |

| Top pile height | 950mm2 |

| Top speed | 4200pcs/h |

| Power | 0.92KW |

| Power supply | 3P~380V/50HZ |

| Total weight | 700kg |

| Overall size | 2700×2050×2750mm3 |

If you have any enquiry about quotation or cooperation, please feel free to email us jbprint@cn-jinbao.com or use thefollowing enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products

Imagine a high-end cosmetic box or a limited-edition beverage bottle. It catches your eye immediately, shimmering with a sophisticated, metallic design that feels bo...

Release Time:2026-01-27A well-designed, semi-automatic screen printing machine optimized for glass products, equipped with a precise registration system, adjustable stroke control, and a r...

Release Time:2025-12-16[Insert Featured Image: Close-up of high-end print samples showing cold foil UV finishing effects, with clear texture and luster contrast][Embed Video: Brief demonst...

Release Time:2025-12-05

GET A QUOTE