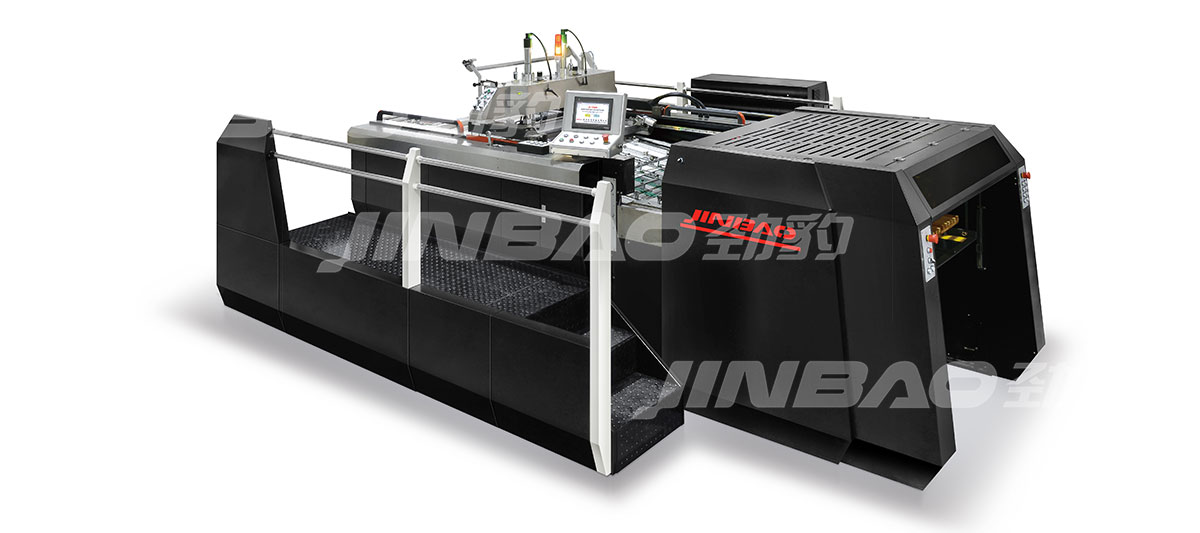

Automatic screen printing press specifications and dimensions

The specifications and dimensions of an automatic screen printing press can vary depending on the specific model and manufacturer.

Small automatic screen printing press:

Workbench area: usually 300mm×400mm or slightly larger, such as 350mm×500mm.

Printing range: generally 200mm×300mm or slightly larger, such as 250mm×400mm.

Equipment size: usually 800mm×600mm×500mm, sometimes larger, such as 1000mm×800mm×600mm.

Other specifications: The screen frame size is 360mm×460mm, and the screen size is 300mm×400mm.

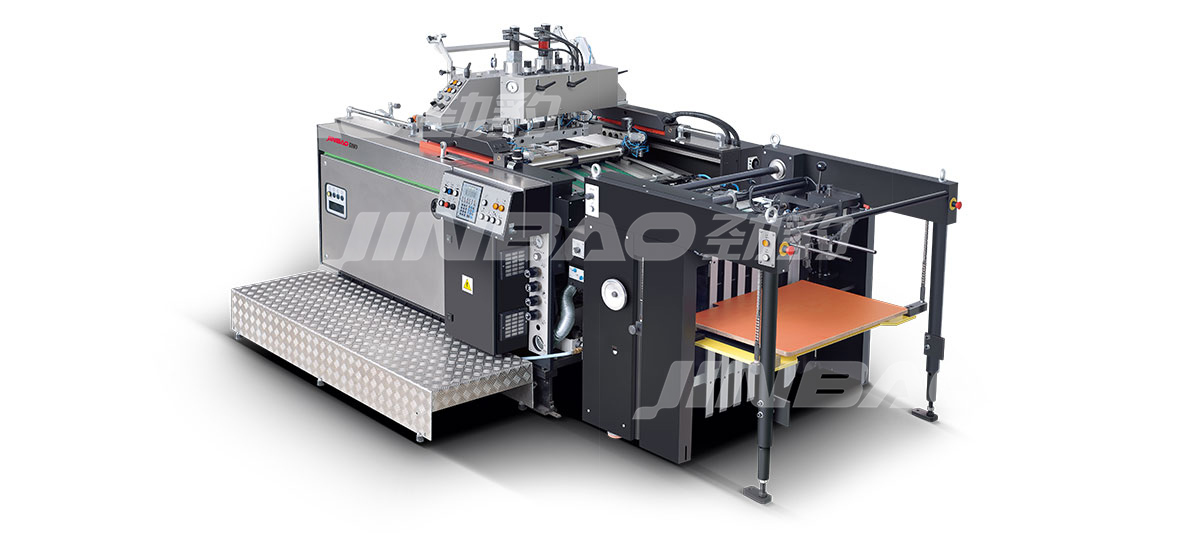

Large screen printing machine:

Maximum printing area: 300×500mm.

Workbench size: 400×600mm.

Screen frame size: 500×700mm.

Power supply: 220V 50-60Hz/500W.

Overall dimensions: 950×760×1650mm.

Here are some general parameters that you can expect:

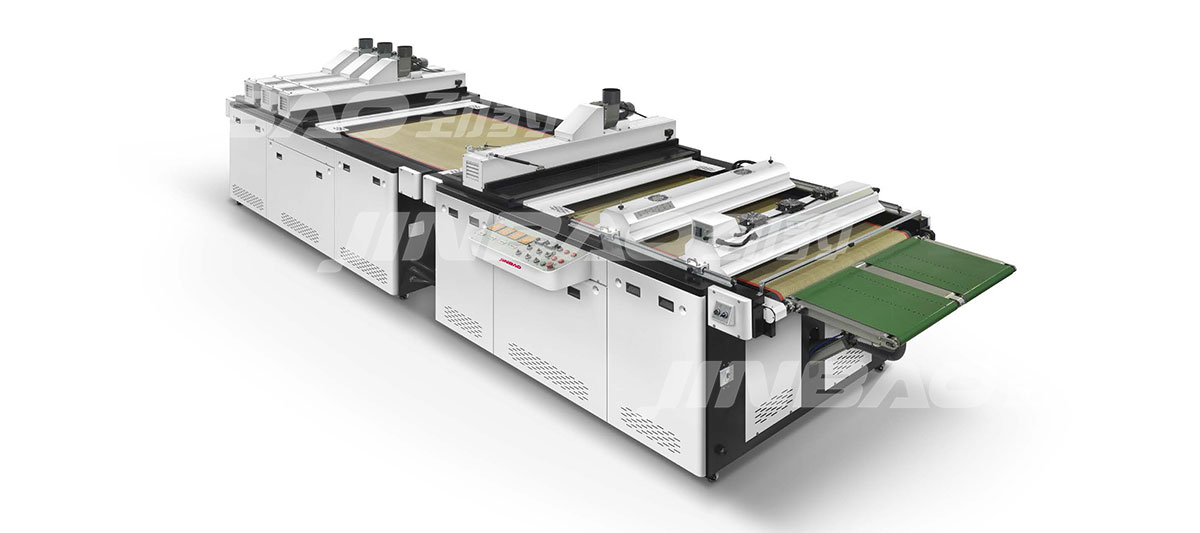

Maximum print area: This typically ranges from around 300mm x 500mm to 800mm x 1200mm or larger.

Number of colors: Automatic screen printing machines can have anything from 1 to 12 or more colors, with each color requiring its own screen and ink station.

Printing speed: The speed at which an automatic screen printing machine can print varies depending on factors such as the number of colors, the size of the print area, and the complexity of the design. However, typical speeds range from around 600 to 1000 impressions per hour.

Dimensions: These can vary widely depending on the specific model and features, but generally automatic screen printing machines are large and require a significant amount of floor space. A typical range would be from 3m x 2m to 5m x 5m or even larger.

It is important to note that these are only rough estimates and the actual specifications and dimensions of your automatic screen printing press will depend on the specific model and manufacturer.