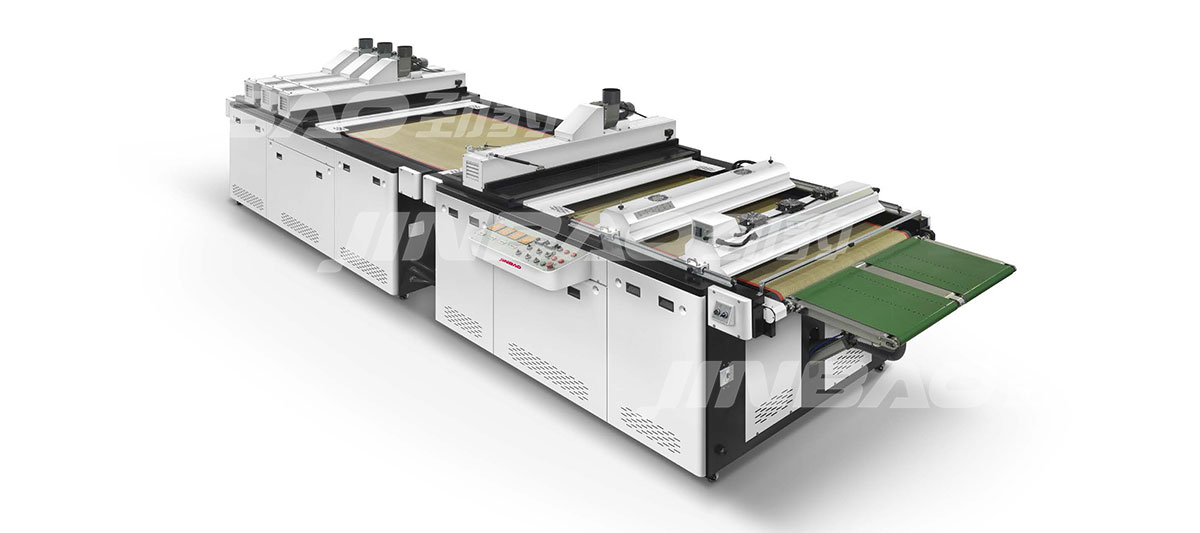

Full Automatic Screen Printing Machine -Cut Costs & Boost Consistency

If you're searching for a "full automatic screen printing machine," you're not just browsing for a new piece of equipment. You're hunting for a solution. You're likely wrestling with the high costs of skilled labor, the frustrating inconsistencies in your print quality, and the sheer physical demand that's burning out your team. You need production to be faster, more reliable, and honestly, more profitable. The direct answer is that a modern full automatic screen printing machine is engineered specifically to conquer these challenges. By automating the entire process from paste dispensing to curing, it dramatically cuts labor dependency, reduces waste, and ensures that the thousandth shirt looks as pristine as the first. This isn't just an upgrade; it's a transformation of your shop's core capabilities. In this deep dive, we'll pull back the curtain on how brands like Jinbao are building these automated textile printing systems that don't just promise change—they deliver a tangible return on investment from day one.

The Real Price of "The Old Way"

Walk into any shop relying on manual or semi-automatic presses, and you'll feel the rhythm—or lack thereof. It's a ballet of highly skilled, and increasingly hard-to-find, operators. The true cost here is a silent killer.

A fully automatic screen printing press eliminates this human variable. We're talking about a system that applies the same precise pressure, the same exact stroke, and the same flash dryer timing, every single time. The operational cost savings aren't just about needing fewer bodies; they're about the elimination of costly errors. Think about the ink you save by not having to throw away misprinted garments. Consider the energy you conserve with efficient, timed curing systems. The financial bleed from the "old way" is multifaceted, and automation is the tourniquet.

Engineering Flawless Repeats with an Automatic Screen Printing System

"Production consistency" can sound like a bland corporate term. But on the shop floor, it's everything. It's the trust your clients have in you. It's the reason a global brand will choose you over a competitor.

What does "flawless" actually mean in automatic screen printing? It's not a vague concept; it's a set of measurable engineering parameters:

•Registration Accuracy: A high-performance automatic screen printing machine uses servo motors and precision guides to achieve registration tolerances within ±0.1 mm. This means razor-sharp edges and perfect alignment, even on the most complex designs.

•Ink Deposit Control: Manual printing is a feel-based art. Automation is a science. The squeegee speed, angle, and pressure are digitally controlled and repeatable. This ensures the color density and hand-feel of the print are identical across the entire run.

•Curing Perfection: Inconsistent curing is a ghost in the machine. Under-cured prints wash out; over-cured prints crack and feel stiff. An integrated fully automatic printing system often features a synchronized conveyor dryer that maintains a precise temperature profile, guaranteeing every garment is cured exactly to specification.

This level of production consistency is what allows you to confidently take on large orders from demanding clients. It's your ticket into the big leagues.

Not Just a Machine, a Production Partner

Now, anyone can bolt together a bunch of servos and call it "automatic." The magic—and this is where my perspective comes from years in this industry—lies in the design philosophy. Jinbao doesn't just build machines; they build workflow solutions.

I've seen cheaper automatic screen printing equipment that looks good on a spec sheet but fails in the real world. They vibrate excessively at high speeds, leading to "ghosting." Their user interfaces are clunky and require a computer science degree to operate. Jinbao approaches it differently. Their engineers spend time in shops, watching, listening. They understand that a machine must be robust, yes, but also intuitive.

Take their Jinbao Jaguar series. It’s not just about its blistering speed. It's about the little things. The quick-release squeegee and floodbar assemblies that cut changeover time from minutes to seconds. The user-friendly HMI (Human-Machine Interface) that allows an operator to set up a complex job with just a few taps. They offer customized automation solutions—maybe you need a specific pallet size for baby onesies or a unique ink circulation system for specialty gels. This flexibility is crucial. You're not buying an off-the-shelf product; you're integrating a partner that adapts to your unique business.

From Capital Expenditure to Strategic Investment: Calculating Your ROI

Let's talk numbers, because that's what convinces the CFO. The upfront cost of a full automatic screen printing machine is significant. There's no sugar-coating that. But the narrative must shift from seeing it as a simple cost to understanding it as a strategic investment.

Here’s a simplified breakdown. Let's assume a manual press setup can produce 180 shirts per hour with a team of 4. A Jinbao automatic system can easily hit 600-900 shirts per hour with a single operator loading and unloading.

| Cost Factor | Manual Setup | Jinbao Automatic System | Notes |

|---|---|---|---|

| Labor (per hour) | $120 (4 people @ $30/hr) | $30 (1 person) | Immediate cost reduction of $90/hr |

| Output (per hour) | 180 pcs | 720 pcs | 4x increase in production capacity |

| Scrap Rate | ~5% | ~1% | Savings on garments and ink |

| Effective Cost per Shirt | ~$0.72 | ~$0.05 | A dramatic 14x reduction in direct cost |

Data is a simplified model for illustration based on industry averages and typical performance gains.

Beyond the hard numbers, consider the soft benefits. What is the value of delivering every order on time because your machine doesn't get tired? What is the worth of winning a million-dollar contract because you can guarantee a level of quality your competitors can't? The ROI isn't just about payback period; it's about the new market opportunities you can seize.

A Scene from an Automated Future

Imagine this: It's 8 AM on a Monday. You have five different orders to run, totaling 5,000 shirts. Instead of the pre-shift hustle of assigning tasks and hoping your team is focused, your single operator simply selects "Job 001" on the Jinbao HMI.

The machine whirs to life. Pallets move with robotic precision. The squeegee does its dance, depositing ink with metronomic consistency. The printed shirts glide seamlessly into the curing oven. There is no drama. There is no variation. The operator is now free to manage quality control, perform minor maintenance, and prepare for the next job. The atmosphere is calm, focused, and productive. This isn't a far-off dream; this is the daily reality for shops that have made the leap to a fully automatic screen printing solution.

Ready to Transform Your Production Line?

The data is clear. The technology is proven. The question is no longer if you should automate, but when and with whom. Choosing a partner like Jinbao means selecting a path of intelligent automation, backed by engineering excellence and a deep understanding of your real-world challenges.

Stop letting operational costs and quality inconsistencies cap your growth.Contact JINBAO, personalized demo with a Jinbao expert and see how a full automatic screen printing machine can be customized for your specific needs. Let's calculate your unique ROI and build a path to a more profitable, consistent, and sustainable future for your business.

This article was crafted with the assistance of AI for research and structural outlining, with final content, analysis, and personal perspectives developed by a human industry expert to ensure depth and authenticity.