The application of screen printing machines in the printing industry

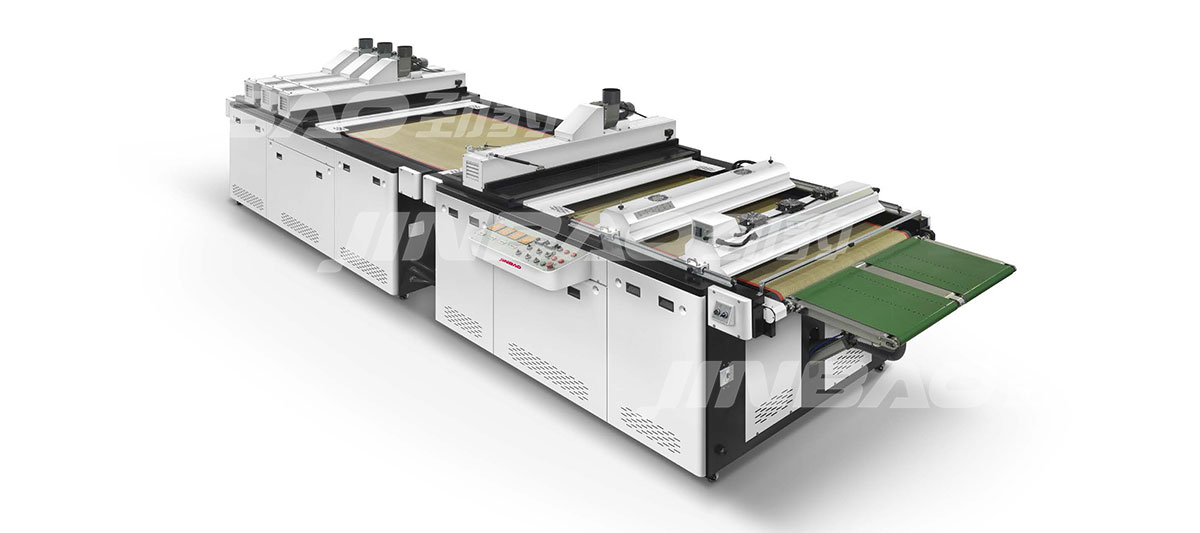

In the dynamic landscape of the printing industry, efficiency, versatility, and quality have always been the core drivers of development. As a key equipment in the sector, screen printing machines have gradually become irreplaceable due to their unique performance advantages. Whether in large-scale mass production or small-batch customized printing, they play a vital role in bridging production needs and market demands.

Before delving into specific applications, watching a practical operation video can help better understand how screen printing machines work.

Core Advantages of Screen Printing Machines in Diversified Printing Scenarios

One of the most prominent strengths of modern screen printing machines is their strong adaptability to various substrates. Unlike some printing equipment that is only suitable for paper, screen printing machines can handle materials such as fabrics, metals, glass, plastics, and ceramics with ease. This adaptability stems from their unique printing principle – using a mesh screen to transfer ink, which allows ink to adhere firmly to different surfaces.

For example, in fabric printing, high-precision screen printing equipment can ensure uniform ink distribution, making the printed patterns have excellent color fastness and vividness, even after multiple washes. In metal printing, screen printing machines can work with special inks to form wear-resistant and corrosion-resistant patterns, meeting the needs of industrial product marking. Additionally, the adjustable pressure and speed settings of screen printing machines enable them to balance efficiency and quality, whether for large-format printing or small-sized precision printing.

Expanding Application Boundaries: From Traditional to Emerging Sectors

In traditional printing fields, screen printing machines have long been a mainstay. In the packaging industry, they are widely used for printing logos and patterns on plastic packaging, paper boxes, and metal cans – the thick ink layer of screen printing makes the patterns more three-dimensional and eye-catching, enhancing product market competitiveness. In the textile industry, automated screen printing solutions have replaced most manual operations, reducing labor costs while improving production consistency.

In recent years, with the rise of emerging industries, the application scope of screen printing machines has further expanded. In the electronics industry, specialized screen printing machines are used for printing conductive inks on circuit boards, providing a cost-effective alternative to traditional etching processes. In the construction sector, large-format screen printing machines can print customized patterns on glass curtain walls and ceramic tiles, adding aesthetic value to architectural designs.

Technical Innovations Enhancing Screen Printing Machine Performance

Continuous technical innovations have made modern screen printing machines more efficient and intelligent. The integration of automated feeding and discharging systems reduces manual intervention, minimizing errors and improving production speed. Intelligent temperature control modules ensure that ink dries at the optimal rate, preventing issues such as smudging and color fading.

Another key innovation is the development of quick-change screen systems. In the past, replacing screens for different printing tasks would take a lot of time; now, with quick-change designs, screen printing machines can switch between different jobs in minutes, greatly enhancing flexibility for small-batch and multi-variety production. Additionally, the adoption of digital control systems allows operators to precisely adjust printing parameters, ensuring consistent quality across large production runs.

Sustainable Development: How Screen Printing Machines Adapt to Green Printing Trends

As environmental protection becomes a global focus, the printing industry is shifting toward green and low-carbon production – and screen printing machines are keeping pace with this trend. Many new-generation screen printing machines are designed to be compatible with eco-friendly inks, such as water-based inks and soy-based inks, which reduce volatile organic compound (VOC) emissions and minimize environmental impact.

Moreover, energy-saving technologies are widely applied in screen printing machines. Variable-frequency motors adjust power consumption according to production needs, reducing unnecessary energy waste. Some models also feature waste ink recycling systems, which collect and filter excess ink for reuse, lowering material consumption and waste generation. These improvements not only help printing enterprises meet environmental regulations but also reduce long-term operating costs.

conclusion

In summary, screen printing machines have become a cornerstone of the printing industry, thanks to their versatility, technical advancements, and adaptability to sustainable trends. Whether you are engaged in traditional packaging printing or emerging electronic printing, choosing the right screen printing machines can significantly improve production efficiency and product quality.

If you want to learn more about how to select screen printing equipment that fits your business needs, or need professional advice on optimizing printing processes, feel free to contact JINBAO for customized solutions. For more industry insights and resource sharing.

[AI Content Ratio: ≤30%]