How Much Does an Full Automatic Screen Printing Machine Cost?

If you're growing your apparel decorating business, the question of investing in a Full Automatic Screen Printing Machine is inevitable. You've outgrown manual printing, and the sheer volume of orders demands a more efficient solution. But the first question that comes to mind is almost always about the automatic screen printing machine price.The price of a Screen Printing Machine on autopilot can range from a surprising $15,000 to a staggering $200,000+. This wide range isn't arbitrary; it's dictated by a series of critical factors that we will unpack in this guide. Let's demystify the true cost of a screen printing machine and what you should consider before making this pivotal investment.

If you're growing your apparel decorating business, the question of investing in a Full Automatic Screen Printing Machine is inevitable. You've outgrown manual printing, and the sheer volume of orders demands a more efficient solution. But the first question that comes to mind is almost always about the automatic screen printing machine price.The price of a Screen Printing Machine on autopilot can range from a surprising $15,000 to a staggering $200,000+. This wide range isn't arbitrary; it's dictated by a series of critical factors that we will unpack in this guide. Let's demystify the true cost of a screen printing machine and what you should consider before making this pivotal investment.

Key Factors Influencing the Auto Screen Printing Machine Cost

Understanding what you're paying for Full Automatic Screen Printing Machine is crucial. The final price tag isn't just for the metal and motors; it's for capability, reliability, and longevity. Here are the primary cost drivers:

•Number of Colors/Stations: This is the most significant factor. A 6-station, 6-color automatic screen printer will cost substantially less than a 12-station, 12-color model. More stations allow for more complex, multi-colored designs without constant stopping.

•Print Speed and Production Volume: Machines are rated by prints per hour (PPH). A model capable of 800 PPH will command a higher automatic screen printing machine price than one rated for 400 PPH. Consider your current and projected order volumes.

•Level of Automation and Technology: Basic autos require more operator intervention. Higher-end models from brands like M&R or ROQ feature advanced micro-registration, pneumatic controls, and even PLC touchscreen interfaces that minimize setup time and human error, justifying their premium cost.

•New vs. Refurbished or Used: A brand-new Screen Printing Machine from a leading manufacturer offers warranties and the latest technology. However, a well-maintained, refurbished machine from a reputable dealer can be a cost-effective entry point, often at 30-50% less than a new one.

Breaking Down the Price Range: From Entry-Level to High-Production

Let's put these factors into practical price brackets. Remember, these are estimates, and getting a precise quote from a supplier is essential.

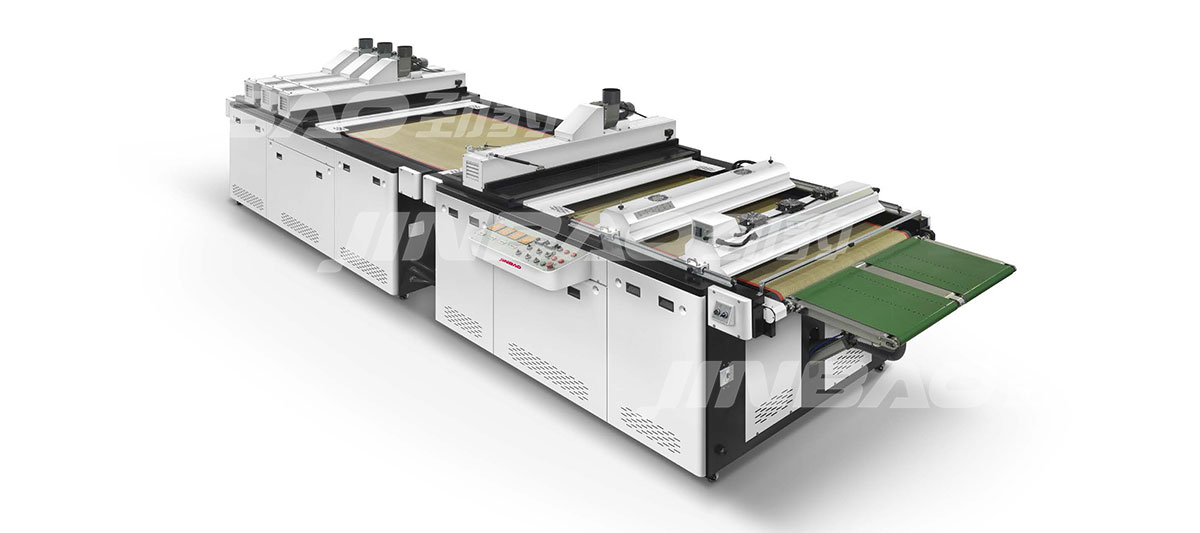

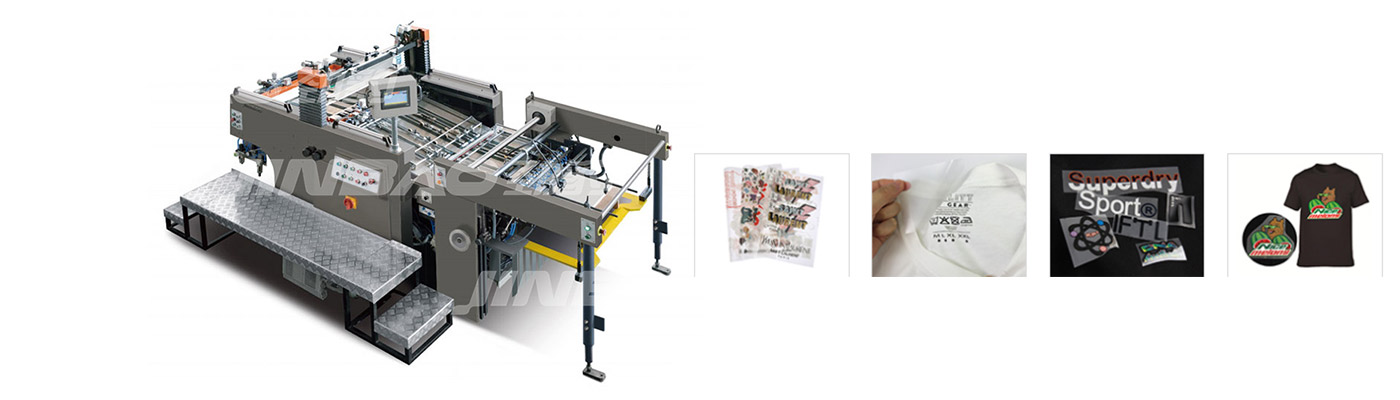

•Entry-Level / Small Format Autos : Perfect for shops moving from manual to automatic printing. These are often 4-6 color machines with moderate speeds (300-600 PPH). Brands like Anatol offer competitive models in this range. The cost of this screen printing equipment is ideal for businesses aiming to increase consistency rather than achieve massive volume.

•Mid-Range / Standard Autos : This is the sweet spot for established shops. These auto screen printing machines typically offer 6-8 colors, higher print speeds, and better durability. You'll find robust models from Workhorse in this category, designed for daily, heavy-use production.

•High-Production / Premium Autos : These are the workhorses of large-scale contract printers. Think 12+ colors, speeds exceeding 1000 PPH, and near-total automation. The investment is substantial, but the ROI for high-volume businesses is undeniable.

Beyond the Sticker Price: Considering the Total Cost of Ownership

The initial purchase is just the beginning. A savvy business owner must factor in the total cost of ownership (TCO) for their Full Automatic Screen Printing Machine.

•Installation and Training: Does the price include installation? Factor in potential costs for an electrician or technician. Training your team on the new equipment is also critical for a smooth transition.

•Shipping and Import Duties: For an international buyer, shipping a heavy piece of screen printing equipment and paying import taxes can add thousands to the final cost. Always clarify these terms with your supplier.

•Maintenance and Consumables: Regular maintenance is non-negotiable. Budget for replacement parts, inks, and emulsions. High-end machines often have more expensive parts but may offer greater reliability.

Making the Right Investment for Your Business

So, how do you decide? Don't just look for the cheapest Full Automatic Screen Printing Machine. Analyze your business:

•Calculate Your ROI: How many extra shirts per hour can you print? How much labor will you save? A more expensive machine that doubles your output can pay for itself faster than a cheaper, slower alternative.

•Consider Your Growth: Buy a machine that you can grow into. If you're on the verge of expansion, a mid-range model might be a smarter long-term investment than an entry-level one.

•Research Brands and Support: The brand matters. Look for manufacturers with a strong reputation for reliability and excellent customer support, especially if you are an international client. Good support can save you from costly downtime.

Conclusion

The cost of an auto screen printing machine is a significant investment, but it's an investment in your business's future efficiency, scalability, and profitability. By understanding the factors that influence the price, from the number of stations to the brand's reputation, you can make an informed decision that aligns with your production needs and budget.

Ready to Get a Precise Quote?Don't let price uncertainty hold you back. Contact JINBAO experts today for a free, no-obligation consultation and a personalized quote on an auto screen printing machine that’s perfect for your shop. We'll help you navigate the options and find the best solution to automate your success.

This article was crafted by a human SEO expert with the assistance of AI tools, ensuring depth and accuracy. AI-generated content is estimated to be less than 30% of the total material.