How much is an automatic screen printing machine

How much is an automatic screen printing machine?

The cost of an automatic screen printing machine can vary widely, depending on a number of factors including brand, model, size, features, and production capacity. On average, automatic screen printing machines range in price from a few thousand dollars to tens of thousands of dollars.

Entry-level automatic screen printers with basic features and a smaller print area start at around $10,000 to $15,000. These machines typically have fewer colors and limited automation capabilities.

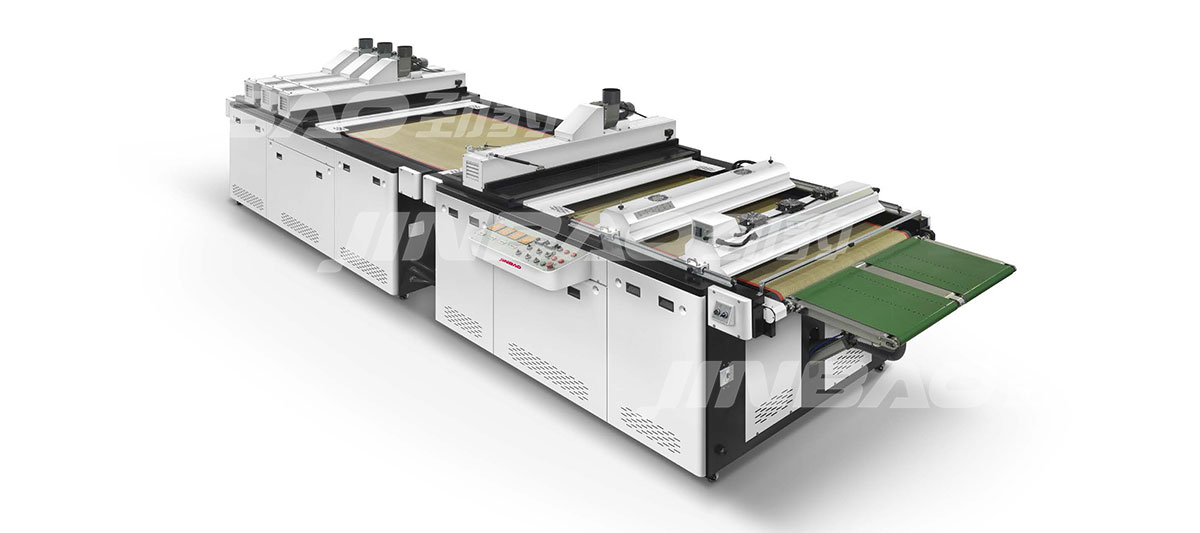

Mid-range automatic screen printing machines with additional features, larger print areas, and higher production capacities can range from $20,000 to $50,000. These machines offer greater flexibility and efficiency in terms of print quality and production speed.

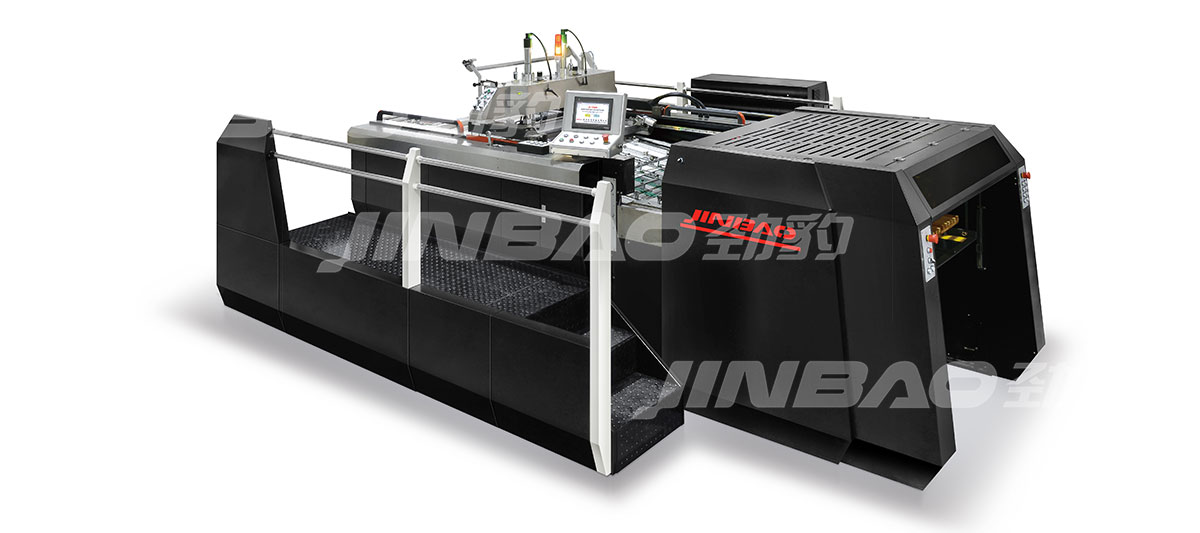

High-end or industrial-grade automatic screen printing machine with advanced automation, multiple print heads, larger print areas, and special features can cost as much as $100,000 or more. These machines are designed for high-volume production and offer extensive customization and control options.

It is important to note that these price ranges are approximate estimates and actual costs may vary depending on specific requirements, customization options, and other accessories required. It is recommended to review the overall strength of suppliers, compare prices, and consult with reputable screen printing machine suppliers to obtain accurate pricing and determine the right printing machine for your specific needs and budget.

The working principle of automatic screen printing machine:

Taking the commonly used hand-shaped screen printing machine (automatic printing machine) as an example, the working principle of the screen printing machine can be described as follows: the power is transmitted through the transmission mechanism, and the squeegee squeezes the ink and screen printing in motion. version, so that the screen printing plate and the substrate form a nip line, because the screen has tension N1 and N2, a force F2 is generated on the squeegee, and the resilience makes the screen printing plate not touch the substrate except the nip line In contact with each other, the ink passes through the mesh and leaks from the moving nip to the substrate under the action of the extrusion force F1 of the squeegee.

During the printing process, the screen printing plate and the squeegee move relative to each other, and the extrusion force F1 and the rebound force F2 also move synchronously. (Automatic printing press) The blot is smudged. That is, the screen is constantly deformed and rebounded during the printing process.

After unidirectional printing, the squeegee is separated from the substrate together with the screen printing plate, and at the same time, it returns to the ink, that is, completes a printing cycle. The distance between the upper surface of the substrate and the reverse side of the screen printing plate after the ink is returned is called the same plate distance or screen distance, which should generally be 2 to 5mm. When printing by hand, the technique and proficiency of the operator directly affect the formation of the embossing line.

In practice, screen printing workers have accumulated a lot of valuable experience, which can be summarized into six points, that is, to ensure the linearity, uniformity, equiangularity, pressure equalization, centering, and verticality of the squeegee in motion. That is to say, when printing, the squeegee should move forward in a straight line, and should not shake from side to side; it should not be slow in front and fast in back, fast in front and slow in back, or suddenly slow and fast; the inclination angle to the ink plate should remain unchanged, and special attention should be paid to overcoming the inclination angle A common problem that gradually increases; the printing pressure should be kept uniform; the distance between the squeegee and the inner sides of the screen frame should be kept equal; the ink board should be kept perpendicular to the frame.