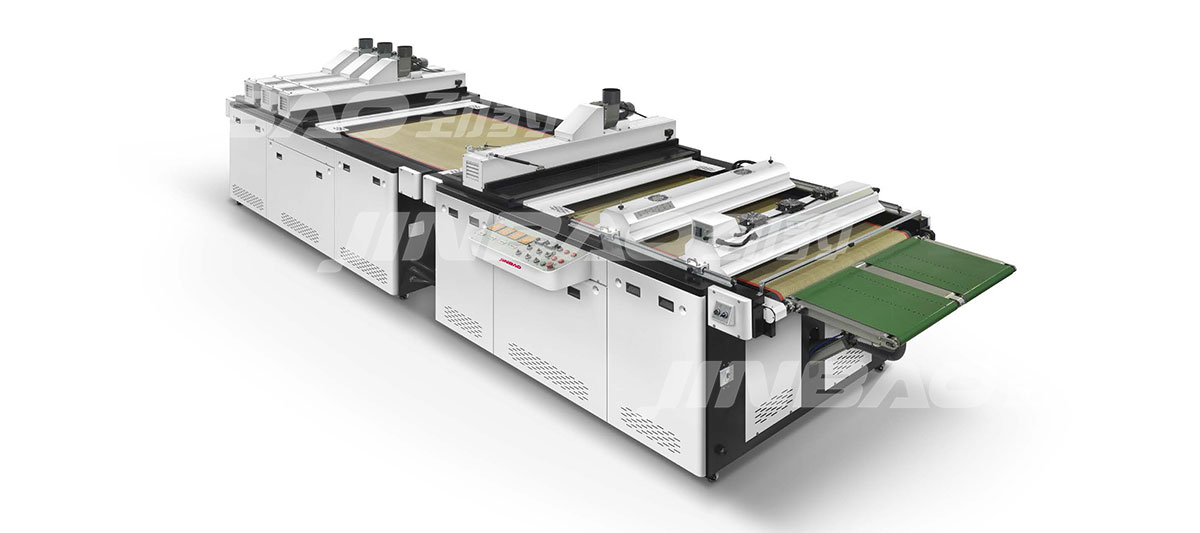

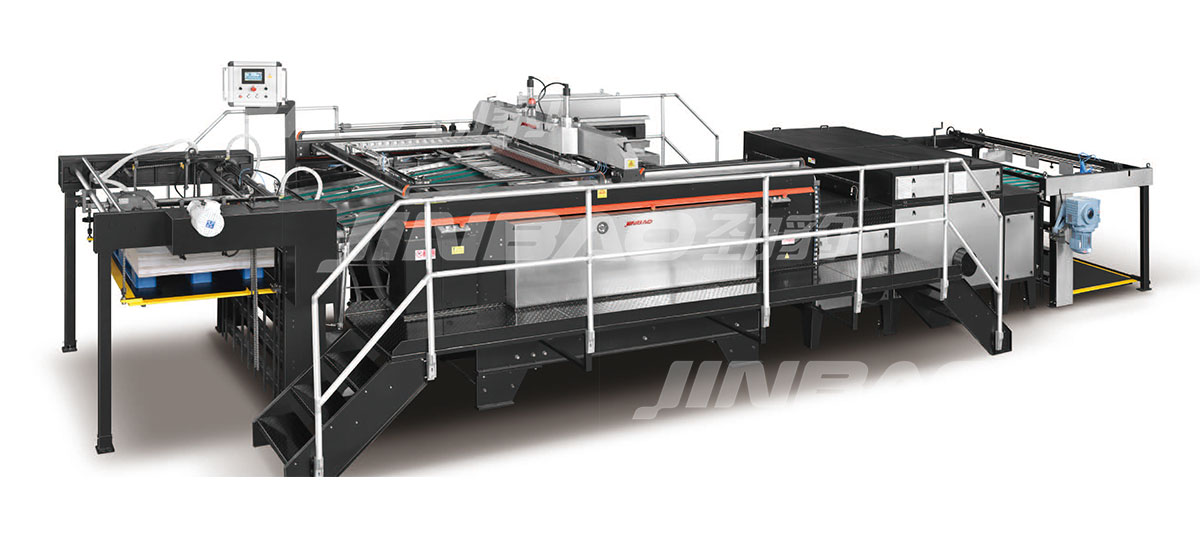

How to make silk screen printing machine

Screen printing technology is commonly used for flat screen printing of products. It prints some colors or patterns on the surface of the product to make the product look rich and have packaging value. Of course, some electronic products around our lives can also be printed. , below Zhejiang Jinbao Machinery Co., Ltd will tell you about the production method of screen printing machine.

How to make a silk screen printing machine

Frame: Start by building or obtaining a sturdy frame to hold the wire mesh tightly. The frame should be made of durable materials such as wood or aluminum.

Screen printing: A mesh fabric (usually silk, but polyester is also commonly used) is stretched tightly over a frame, making sure it is smooth and free of any wrinkles. Secure the fabric to the frame using staples, adhesive, or a clamping system.

Emulsion coating: Apply photosensitive emulsion to the screen. This emulsion will create a template for the printing process. Apply the lotion evenly to the screen according to the instructions that come with the lotion and allow it to dry in a dark environment.

Artwork Preparation: Prepare your desired artwork or design on transparencies or digital formats. If necessary, be sure to invert the design as it will print as a mirror image.

Exposure: Place the prepared artwork on a dry, lotion-coated screen. Expose the screen to a strong light source or special exposure device. The light will harden the emulsion in areas not covered by the artwork, creating a stencil.

Wash: Rinse the screen with water to remove unexposed emulsion, leaving open areas through which ink will pass during printing. Use a mild spray or sponge to avoid damaging delicate areas of the stencil.

Installation and Registration: Install the silk screen onto the silk screen printing machine, making sure it is firmly connected. Set positioning guides or marks to accurately align artwork on each print.

Printing: Apply ink to one end of the screen and use a squeegee to evenly distribute the ink over the design while applying consistent pressure. The ink will pass through the open areas of the stencil to the printing surface below.

Repeat: Lift the screen, reposition it for the next print, and repeat the printing process for each item or color layer in the design.

Screen printing process arrangement of silk screen printing machine

Screen printing is a direct printing method, and there are three process arrangements:

① Cardboard → screen printing → post-printing processing, that is, screen printing is first performed on corrugated cardboard or other cardboard, and then made into cartons and carton products as needed;

② Carton → Screen printing, that is, screen printing directly on the made corrugated carton or other cartons or cartons;

③ Secondary processing, that is, screen printing is first performed on the cardboard, and then made into corrugated cardboard as needed, and then made into cartons and carton products.

silk screen printing machine application fields

①Paper packaging industry

There will be many screen printing patterns on the paper. Using the screen printing machine can make the ink layer of each pattern thick and three-dimensional, and improve the quality of product packaging. It is mainly seen in the packaging of some gifts and high-end commodities, such as cigarettes, wine, cosmetics, nutrition products, and high-end footwear, etc.

②Ceramic packaging industry

On ceramic products, in order to increase the beauty of the ceramic products, various patterns will be painted on the ceramic products. The patterns are also realized through a screen printing machine. Ceramic screen printing is divided into direct method and indirect method. The direct method is to use a screen printing screen to print the image directly onto the ceramic embryo, and then apply glaze and fire it into porcelain; the indirect method is to transfer the screen-printed decals to the ceramic vessel.

③Glass packaging industry

There will be a lot of text or patterns on the glass container products to introduce the products. Oil, salt, sauce, and vinegar used in family life, as well as beer, beverages, liquor, etc., are all packaged using screen printing machines.

④Plastic packaging industry

Plastic film can be used for food packaging, clothing packaging, etc. It can protect the items in the packaging bag from damage due to external influences. There will be simple text or pattern description on the packaging bag, and the contents of the packaging bag.

⑤Metal packaging industry

Metal packaging is mainly for some foods. Since it is easily affected by the external environment, it is placed in metal containers, such as beverage cans, food cans, miscellaneous cans, etc. Screen printing technology requires ink with strong adhesion and high hardness. , good stretchability, and friction resistance.

It’s worth noting that this is a simplified overview and building a professional-grade screen printer may require additional components and equipment, such as a press, drying system, and proper ventilation for ink curing. Consider consulting an expert or refer to a comprehensive guide for detailed instructions on building a screen printing press that suits your specific needs.