The difference between fully automatic and semi auto screen printing machine

In the process of purchasing a screen printing machine, everyone may encounter a common problem, that is, should I buy a fully automatic or semi auto screen printing machine? This is not only related to the price but also related to the use of the product. If you want to buy the most suitable screen printing machine, you must understand the difference between an automatic screen printing machine and the semi-automatic screen printing machine. Below, I will tell you about them difference.

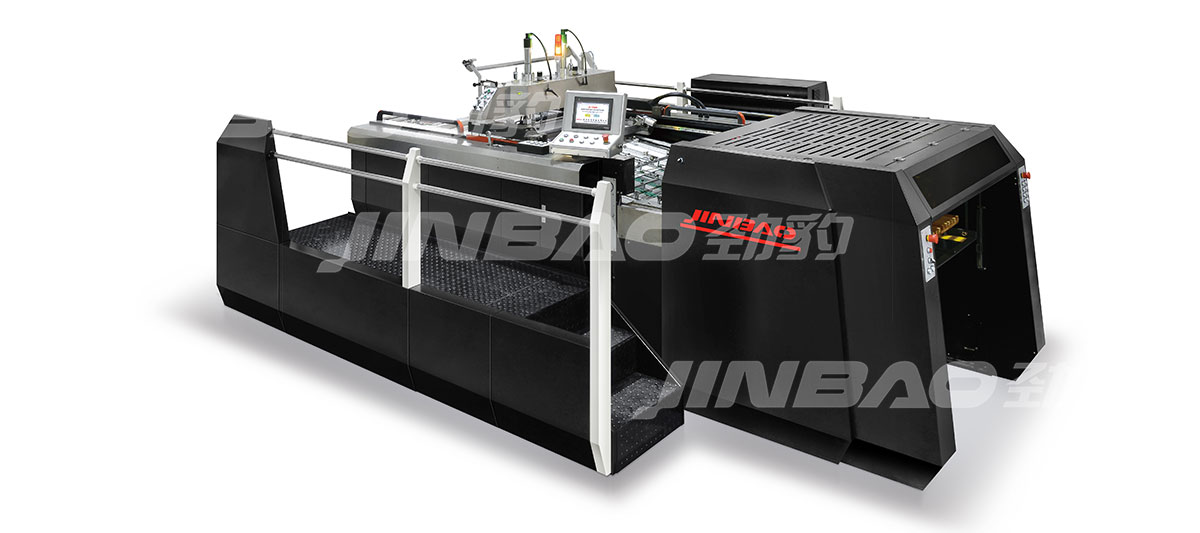

JB-750II 960II 1280II Semi-automatic Screen Printing Machine

What is the difference between the automatic screen printing machine and the semi-automatic screen printing machine? First of all, it is reflected in the operation. The automatic screen printing machine is very simple and convenient to operate. It only needs to be operated by one person without consuming a lot of manpower and material resources. However, the semi-automatic screen printing machine needs to be printed manually, which is inefficient. The automatic screen printing machine can reach 60 per minute, and the semi-automatic screen printing machine may not reach half, and more than two people are needed to cooperate with the machine to print.

They also have something in common. They all have the same characteristics: soft layout, thick ink layer, strong covering power, rich printing quality, strong three-dimensional effect, strong light fastness, and large printing area. Then let's talk about it, what are the advantages of the automatic screen printing machine? Firstly, it is convenient for plate making, and the machine is easy to operate; secondly, the ink layer has strong covering power, and it can be printed in white on black items; the layout is soft and the silkscreen is soft and elastic, so it can also be printed on fragile items, such as glass, ceramics, etc. Its light resistance is very good, it is not affected by temperature and sunlight, and the gloss of the printed items remains unchanged, and the printing methods are flexible and changeable.

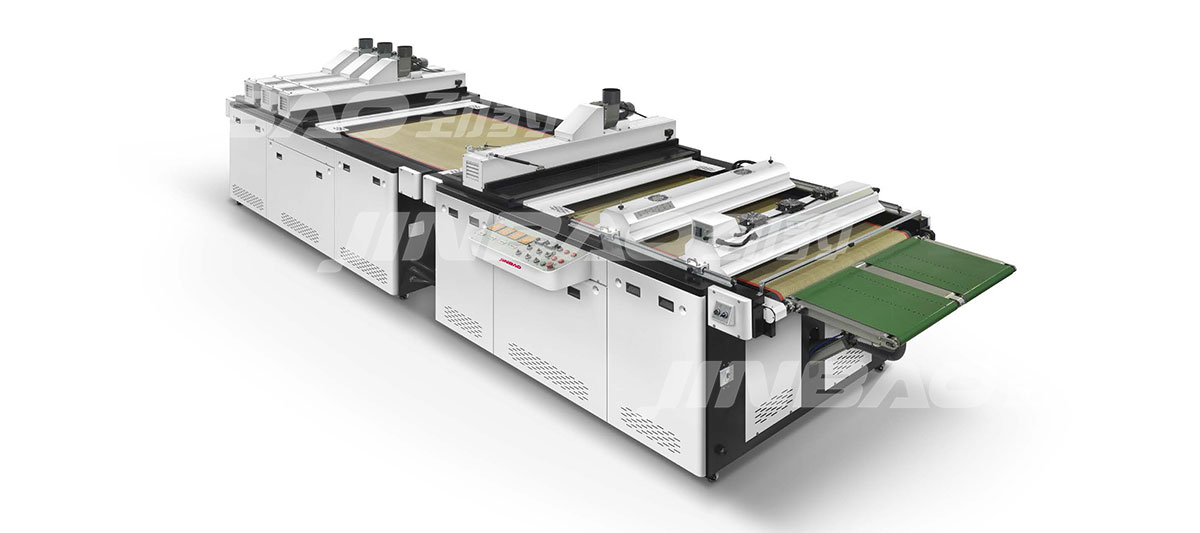

JB-106AS Automatic Servo Motor Control Screen Printing Machine For Spot UV (Servo Version)

How to operate the automatic screen printing machine?

Fully automatic screen printing machines need to be adjusted by the manufacturer and then trained for the on-site staff. Put the printed product in the feeding place, turn on the machine, adjust the parameters and it will start printing automatically. Jinbao Machinery is recommended for purchasing automatic screen printing machines, providing global customers with an overall solution for intelligent automatic screen printing equipment.

Safety tutorial for the use of automatic screen printing machine:

Job Regulations:

1. Before starting the machine, carefully understand the safety warning label requirements on the machine, check whether the wiring within the rated power range is safe, whether the ground wire is reliably grounded, whether the fastening screws are loose or abnormal, and whether the safety signs are complete.

2. Test whether the emergency stop switch of the safety brake plate sensor and the performance of the pedal are normal.

3. Check whether the air pressure of the air source is normal, the normal value is 0.5-0.8MPL, and check whether there is water in the filter cup of the air source dual unit.

4. Turn on the aspirator switch and check whether the aspirator works normally.

5. In manual mode, it is normal for the empty machine to move back and forth and up and down without stopping.

Prepress operation regulations:

1. Confirm whether the screen pattern is consistent with the pattern of the production product model.

2. Adjust the clamp frame of the two-sided screen to the proper position, install the screen, scraper, and ink return knife, correct the screen frame to make it in a horizontal position, adjust the distance between the screen and the platform, and maintain high-precision horizontal printing.

3. Manually, and slightly adjust the printing stroke, speed, and pressure of the scraper and ink return knife. After the above adjustments are correct, the screen plate and the platform are locked and fixed to prevent movement during printing to ensure printing accuracy.

The trial printing stipulates:

1. Place the substrate at an appropriate position in the center of the printing platform, first align the lines with the pattern on the screen, and then position the substrate.

2. Manually test printing, adjust the pressure of the scraper and the ink return knife, so that the pattern appears clear and the color around the pattern is consistent, and then adjust it according to the printing situation.

3. After the above inspection is correct and the surrounding working environment is confirmed to be correct, semi-automatic or fully automatic printing is carried out by means of a foot switch.

Equipment maintenance items:

1. During the maintenance of lifting and left and right printing guide rails, ball guide seats, sliders, and joint bearings, inject fresh butter into the grease gun once every 4 months and add engine oil for 1 week when maintaining the moving parts of the lifting screw rod, chrome-plated rod, and shaft sliding sleeve Once, add spindle oil when maintaining the oil-water separator, check whether the sound of the reducer and motor in the transmission part is normal, and replace the special gear oil once a year during maintenance.

Safety Precautions:

1. When cleaning the machine, the power should be turned off, and the oil stains on the machine should be scrubbed with industrial alcohol.

2. It is forbidden to scrub the screen when the machine is running.

3. Check and maintain the machine every day to prolong its life of the machine.

4. When cleaning the screen, when the head is inserted into the machine, or scrubbing the screen, cut off the power of the machine and press the emergency stop switch.

5. New recruits need to do safety training! And be familiar with the operation manual of the machine and equipment! before starting work.

6. Wires must be installed for printing conductive ink and screen clips of screen printing machines to eliminate static electricity to avoid fire accidents!

For more information about screen printing machines, it is recommended to consult Jinbao Machinery. Founded in 1997 in Wenzhou City near the East China Sea, Zhejiang Jinbao Machinery Co., Ltd. is a prominent manufacturer of automatic screen printing machines and auxiliary printing equipment. Our products are applied extensively in graphics printing, print finishing, transfers for garments, and textile printing among many other kinds of operation.