What is a cylinder screen printing machine, it's working principle and application range

What is a cylinder screen printing machine?

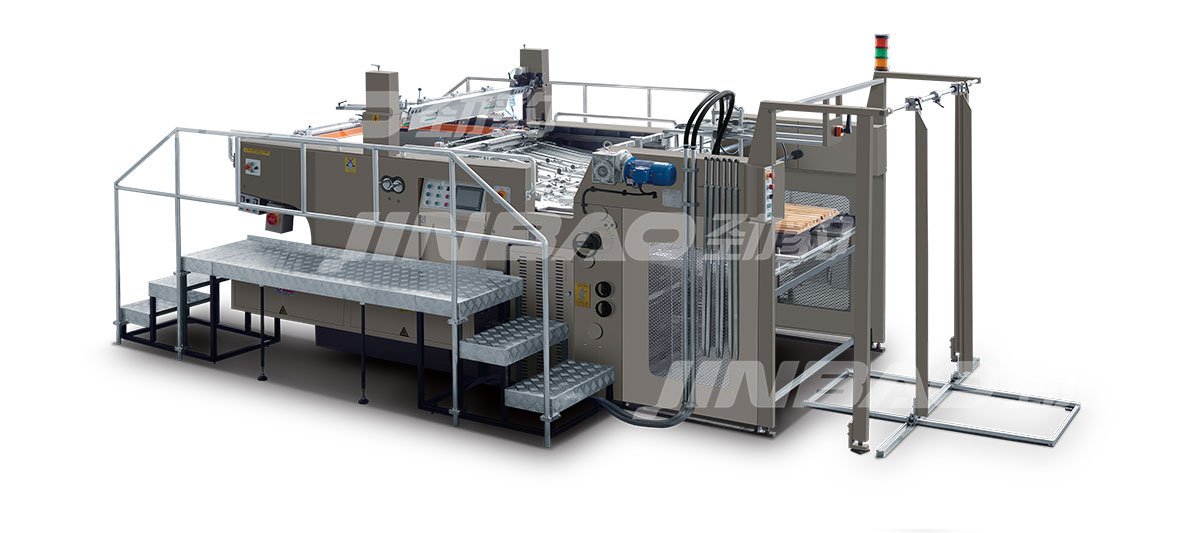

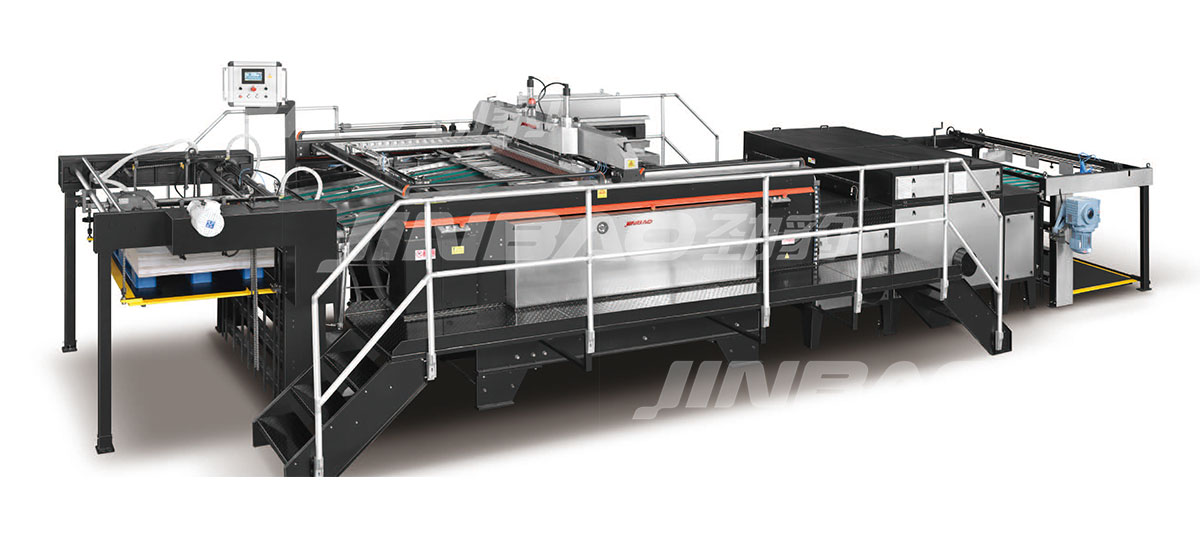

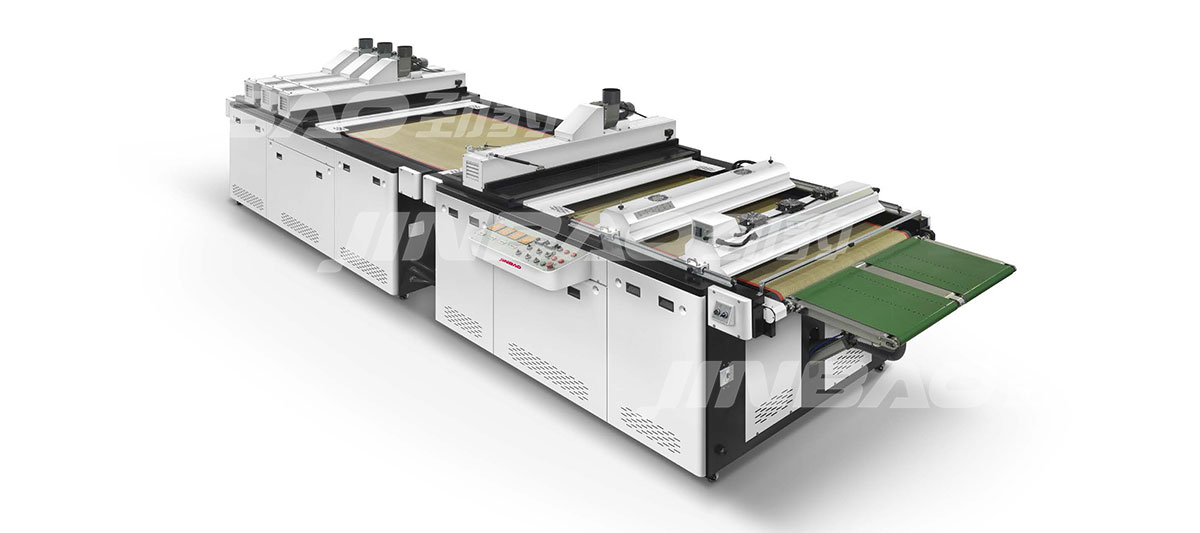

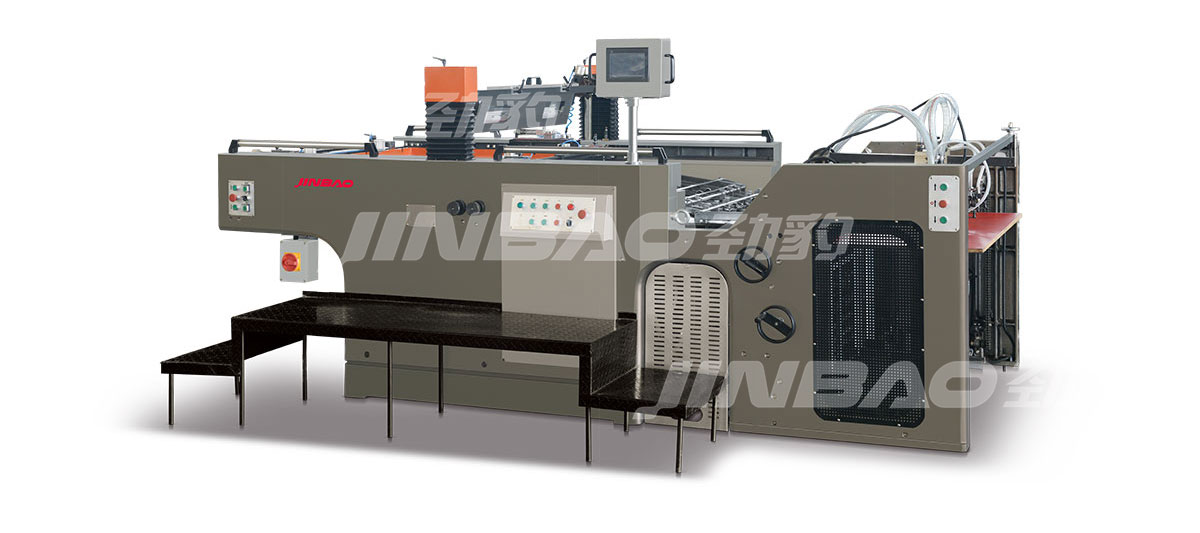

The cylinder screen printing machine manufacturer tells you that the cylinder screen printing machine is a device dedicated to screen printing cylindrical objects. It is usually used to print logos, patterns, text, or other designs on cylinders.

The working principle of the cylinder screen printing machine

The working principle of the cylinder screen printing machine is that the cylinder is placed on the machine and then rotated using a rotary or conveyor belt. The printhead transfers the ink or pigment onto the screen, which is then brought into contact with the surface of the cylinder by pressure, creating the desired pattern or text on the cylinder. It usually consists of the following main components:

Frame: Cylinder screen printing machines usually have a strong frame to support and stabilize the operation of the machine.

Screen system: The screen system is the core part of the cylinder screen printing machine. It consists of one or more wire mesh racks, each of which pulls a wire mesh. The pattern or design on the screen uses the shape and arrangement of the holes to determine where the ink or pigment will be printed.

Transmission system: Cylinder screen printing machines are usually equipped with a transmission system to control the relative movement between the screen and the cylinder object. This can be achieved by electric motors, pneumatics, or manual operation.

Ink supply system: To print, the cylinder screen printing machine needs an ink supply system. It can be manual or automatic and is used to transfer ink or pigments onto the screen and ensure that the correct amount of ink is printed on the cylinder.

Control system: Cylinder screen printing machines are usually equipped with a control system for monitoring and adjusting the operating parameters of the machine, such as printing speed, pressure, position, etc.

Application range of cylinder screen printing machine

Cylinder screen printing machines are widely used in various industries, such as packaging, beverage bottle printing, wine bottle printing, cosmetic container printing, etc. Cylinder screen printing machine manufacturers tell you that it can achieve high-quality, high-efficiency screen printing, and is suitable for the printing needs of various cylindrical objects.

Expand knowledge:

Classification of screen printing machines

Screen printing machines can be divided into flat screen printing machines, curved screen printing machines, rotary screen printing machines, electrostatic screen printing machines, and fully automatic screen printing machines. In the screen printing machine, the screen printing machine is a relatively typical printing equipment, and its printing plate is a screen with crisscross lines and clear warp and weft. All kinds of screen printing equipment have been manufactured, such as plane, curved surface, forming, printing and dyeing, printed circuit, and new runner.

Remark:

Cylinder screen printing machines usually have automated functions to achieve efficient production. At the same time, it also has the functions of adjusting printing position and printing pressure to meet different printing requirements.